Cable assemblies have become an increasingly popular and essential component of many product designs, from consumer electronics to industrial equipment. But what exactly are cable assemblies, and how can product developers incorporate them into their designs? In this comprehensive guide, we'll explore the definition of cable assemblies, the various types available, and the benefits they can bring to product designs.

What are Cable Assemblies?

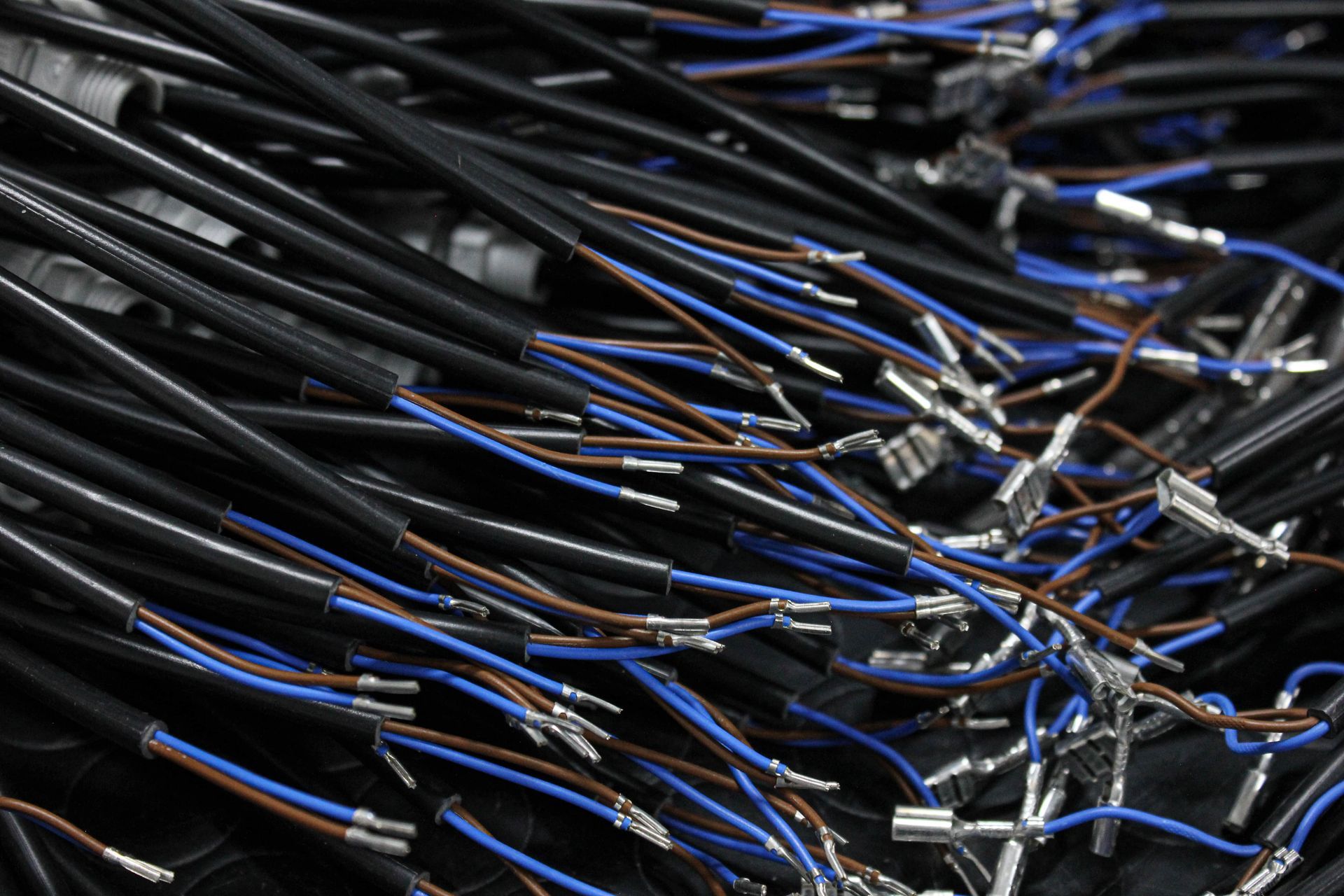

Cable Assemblies are pre-assembled wires and cables that are used to connect two or more devices or components. They come in a variety of configurations and lengths and can be used in many applications, such as consumer electronics, medical equipment, and industrial machinery. Cable Assemblies are typically composed of two or more wires that are connected to a connector at one end, and a splice or terminal at the other.

Cable Assemblies are available in a variety of configurations and materials, including but not limited to PVC, silicone, and Teflon. The type of cable used in a particular assembly is determined by the application, as well as the environment in which the assembly will be used.

Types of Cable Assemblies

There are a variety of types of cable assemblies available to product developers. The most common types are:

- Coaxial Cable Assemblies: Coaxial cable assemblies are composed of a single wire surrounded by an insulating layer. These are frequently used in applications that require high-frequency signals, such as television and radio broadcasts.

- Multi-conductor Cable Assemblies: Multi-conductor cable assemblies are composed of multiple wires that are arranged in either a parallel or twisted configuration. These are often used in applications that require high power, or multiple connections between devices.

- Fiber Optic Cable Assemblies: Fiber Optic cable assemblies are composed of a bundle of optical fibres that are used to transmit data over long distances. These are commonly used in applications that require high-speed data transfer, such as data centres and telecommunications networks.

- Custom Cable Assemblies: Custom cable assemblies are created to fulfil the special needs of a certain application. They are often more expensive than normal Cable Assemblies since they can be configured with a variety of cables and connectors.

Benefits of Cable Assemblies

Cable Assemblies offer several benefits to product developers. They are typically cheaper than buying individual components and are easier to assemble. Additionally, cable assemblies are often more reliable than individual components, as they are designed to meet specific requirements. Finally, cable assemblies can help to reduce the overall size of a product, as they are typically much smaller than individual components.

Cable Assemblies can also help to reduce the complexity of product designs, as they can be used to replace multiple components with a single assembly. This can help to reduce the risk of errors, as well as the time and cost associated with product development.

Conclusion

Cable Assemblies are an essential component of many product designs, from consumer electronics to industrial equipment. They come in a variety of configurations, materials, and lengths, and offer several benefits to product developers, such as cost savings and reliability. By understanding the different types of cable assemblies and the benefits they offer, product developers can incorporate them into their designs to create more efficient and reliable products.

By choosing M-Tek for your

cable assemblies, you will also be doing your part to save the planet. We have achieved a net-zero carbon footprint from our use of electric vehicles, and for every circuit board we build, we plant a tree! Get in touch with one of our experts for help with your SMT and PCB assembly today. Call us on 01189 455377, or follow us on

Twitter to stay up to date with our services.