Our Objectives and Services

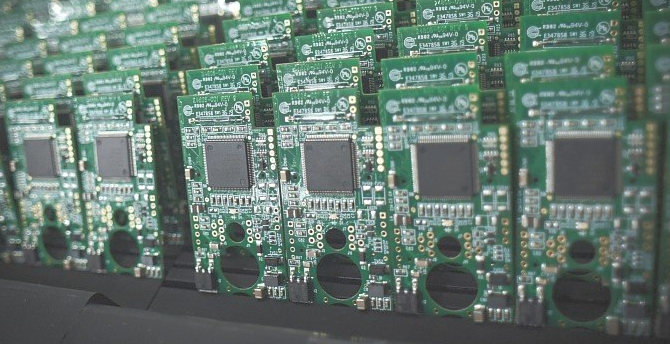

Surface Mount Technology Assembly (SMT)

What is SMT?

SMT is a technique that emerged in the 60s and is currently being widely used by many PCB assembly electronics manufacturers. The process includes PCB components with metal tabs that can be easily soldered to printed circuit boards. It offers higher circuit densities when these parts are fixed at both sides of a PCB using effective soldering methods.

The process of surface mount technology assembly is a fast and efficient way to produce electronic products. It's also one of the best ways to ensure reliability in your product. With SMT, electronic components are mounted directly onto a printed circuit board by machine, instead of soldering them from the underside.

Capabilities & Services

- Sub-Micron X-RAY Inspection

(Digital & Oblique Views)

- SMT & PTH Assembly

(Small, Medium & Volume Production)

- Flexi-Rigid and Flexi Circuits Assemblies

- Package on Package (PoP) Assemblies

- μBGA/BGA Reballing and repairs

- Rapid Prototyping (NPI to Volume)

- Testing & Programming

(Flying Probe, ICT, X-JTAG, ESS)

- Debugging & Product Support

- Complete Box Builds

(inclusive of Cable Assemblies)

- UK & Global Procurement Services based on a Audited Secured Supply Chain

- Vacuum Casting & 3D Prototyping

Why Should You Consider Surface Mount Assembly?

Electronics manufacturers are constantly looking for ways to cut costs and increase productivity. One solution is through surface mount technology assembly (SMT).

SMT assembly allows the machine to pick PCB components out of a tray, supply them with solder paste, put them on the printed circuit board and then wave a soldering iron over it. All before moving on to the next component.

This means that your electronics factory will be able to produce more products in less time with fewer people. However, there are some common misconceptions about SMT assembly versus traditional Through-Hole Assembly (THA).

SMT is a cost-effective and efficient method of contract electronic manufacturing that can help companies increase production and decrease time spent working on their assembly lines. With the increasing demand for higher quality products with lower prices, surface mount technology assembly could be just what manufacturers need to stay competitive.

Our SMT Assembly Services

Manufacturers are always looking for ways to decrease their costs, but have you ever thought about how SMT assembly might be able to help?

What is SMT? Surface mount technology assembly (SMT) is the process of using solder paste to apply components on printed circuit boards. The result of this process is printed circuit boards that are cheaper, have higher yields and lower lead times than traditional PCB assembly methods.

- NPI, Rapid Prototyping, Product Testing & Integration & Complete Box Builds

- Mixed Technology Double Sided PCB assemblies (SMT& Conventional)

- Sub-micron Digital X-RAY Inspection with 70 ° Oblique Viewing Capability

- AOI with Laser Coplanarity Capability Module for QFN, LGAs, BGAs and ICs

- Design for Manufacture & Specialist Repairs Scenario Capability

- Turnkey Product Assembly & Test (Full Procurement)

- Electromechanical Assembly

- Vacuum Casting & 3D Prototyping

What are SMDs?

Surface mount devices (SMDs) are electronic devices with components attached or positioned directly on the surface of the printed circuit board. All of which are created using surface mount technology (SMT).

The through-hole technology building approach, in which PCB components with wire leads are inserted into circuit board holes, has been substantially supplanted in the contract electronic manufacturing industry.

There are many shapes and sizes available for all different types of tasks. Make sure you work with a professional surface mount technology company, like M-TEK, to find the right electronic devices for your specifications.

Our Quality Services Include:

- High accuracy 3D measurement system

- X-ray - investigating for die placement accuracy, BGA shorts, faulty components, counterfeit components and trace and wire bonding contacts/connection

- Complete capability of environmental testing through our Partners

- Mechanical Tests and Control Certified IPC trainers ( IPC-A-610, WHMA-620, J-STD-001)

- Design for Manufacture & Specialist Repairs Scenario Capability

- Instruments for measurement of precision, temperature, force, electricity, tension, ESD, cleanliness

- Execution of Customised Quality Plan for Each Project

- Extensive use of quality tools (Histograms, Ishikawa diagrams, Kaizen Methodologies, etc)

- Equipment and Process Qualification

- Manufacturing Process Validation

- Design for Manufacture Reviews for all New Product Introduction

What is the SMT Process?

The surface mount technology assembly process starts during the design phase when you select which PCB components will be used to create your finished product. A printed circuit board is designed using the MRP software package. Then, it’s time for production to begin.

Production is a stressful time, but it can be made less so with the right planning. The best way to do this? Start early! When designing for manufacturing, it's important not only to ensure your printed circuit board works as intended and meets safety standards but also, to think about how you'll continue once everything has been built.

For example, if there are multiple steps in SMT assembly, then these considerations should happen at an earlier stage. Whereas, soldering together 259 individual components doesn't really require much forethought until it is ready.

It's important to choose the right PCB components for your printed circuit boards. Rely on a competent PCB assembly company that has years of experience with surface mount technology and other PCB assembling services.

Call Our Team

Want to find out more about our PCB assembly services? Speak to our team to find out how we can help you.

Join the Newsletter

We will get back to you as soon as possible

Please try again later