Why Are Printed Circuit Boards Important in Medical Devices?

As technology continues to revolutionise, the way we receive health and medical services has advanced to improve efficiency and customer convenience. Printed circuit boards (PCBs) are a crucial element that facilitates this change in medical devices as these electronics have the ability to carry out a variety of tasks automatically. PCBs can monitor, store and communicate vital patient information to health care professionals, all through a wireless network.

So, in what ways have printed circuit boards advanced modern medicine?

Electronic Health Records

In the 1980s, 1990s, and even the 2000s, electronic health records (EHRs) were extremely poorly integrated systems. In the past, many healthcare systems were not interconnected and systems were kept distinct. Processed orders and paperwork were undertaken independently without a device linking all the relevant data.

However, in modern medicine, and with the use of printed circuit boards in medical devices, such systems have now been combined into a single, unified platform. Consequently, this has improved speed and efficiency; so that patients are receiving the help they require.

EHRs have been upgraded to combine patient data. Yet, by becoming a useful tool, they have the ability to revolutionise data-driven medicine and medical devices. The only method to increase the effectiveness and outcomes of medical procedures and medications is to gather relevant information about the population.

Mobile Health

As more patients choose to receive their medical treatment on the go, mobile health has also grown highly popular. Instead of having to book an appointment at your local GP for your prescription, which can be an effort just trying to get through, there are mobile apps available to speed up this process. Now, through PCB design, patients can access their health records and re-order prescriptions (approved by their GP).

But, this works on the other side too. Healthcare professionals can communicate and receive medical records and data freely by using smartphones. By utilising mobile health, doctors can obtain and view vital information such as patient information, acquire supplies and medications and conduct on-the-spot patient queries.

Worn Medical Devices

The use of worn medical gadgets has become more widespread recently. In actuality, the wearables market is growing at a rate of 16.4% annually. The objective is to create medical devices that patients can wear without difficulty and that is not unpleasant.

To gather useful patient data, the best sensors are utilised. If a person falls and injures themselves, a wearable medical gadget device may also save their life. Even if a patient is ready to become infected from a cut, a wearable device can alert medical experts.

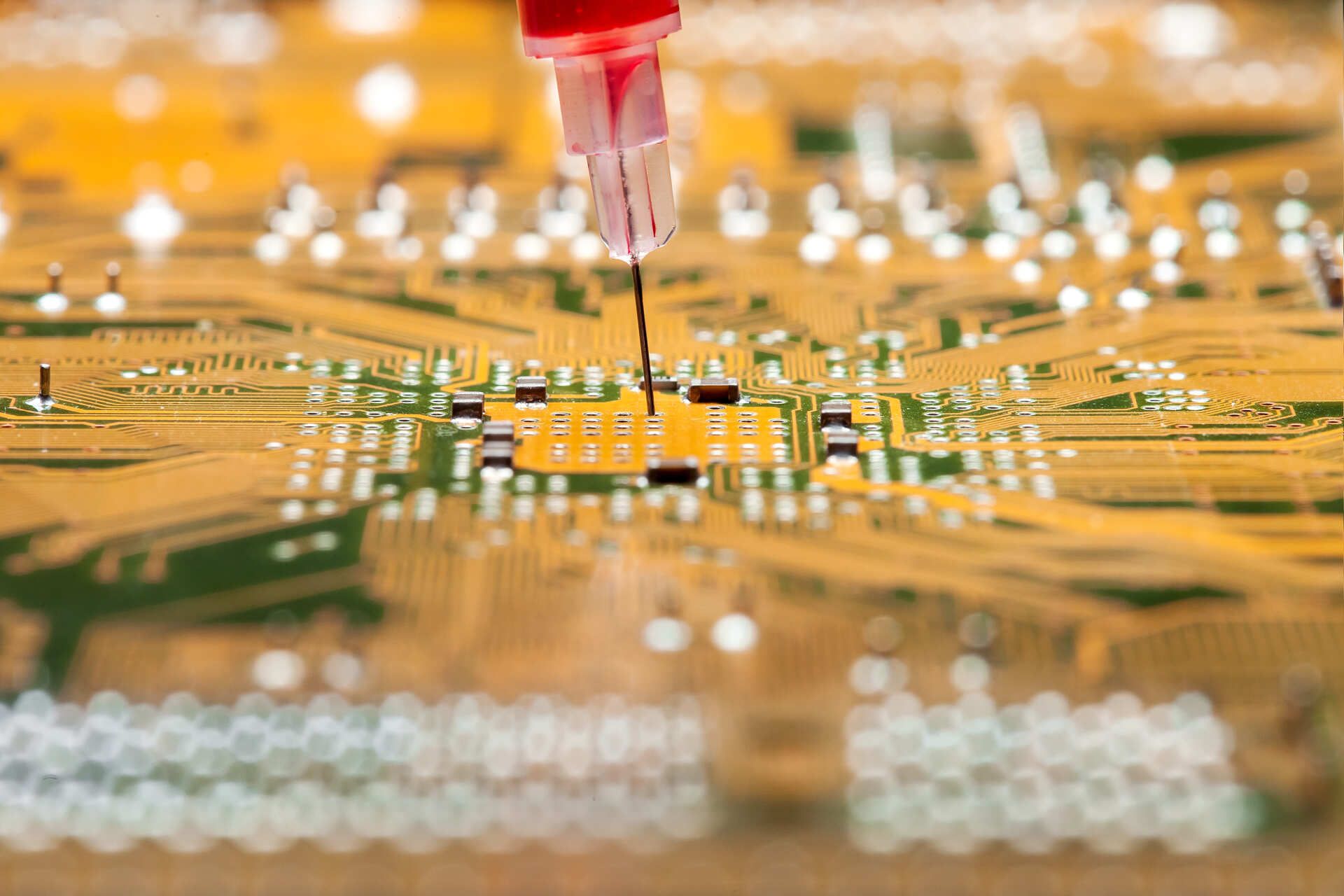

What is PCB?

A printed circuit board refers to the assembly of copper conductors to create electrical connections. Electronic components are mechanically supported by printed circuit boards, allowing a device to be housed in an enclosure.

Here at M-TEK, we understand the importance printed circuit boards can have in a variety of industries, including in modern medicine. As human interaction was limited over the last two years, health care professionals relied on PCB assembly to ensure efficient contact with their patients and to access vital information. For more information on the types of medical devices that have been implemented with PCB design,

read our previous blog here.

Contact one of our SMT and PCB assembly experts today for assistance. Call us at 01189 455377 or follow us on

Twitter to stay up to date on our services.