Are you a product developer who is curious about what PTH Assembly is and the benefits it can bring to your projects? In this article, we will explore what PTH Assembly is and how it can help you develop better products faster.

What is PTH Assembly?

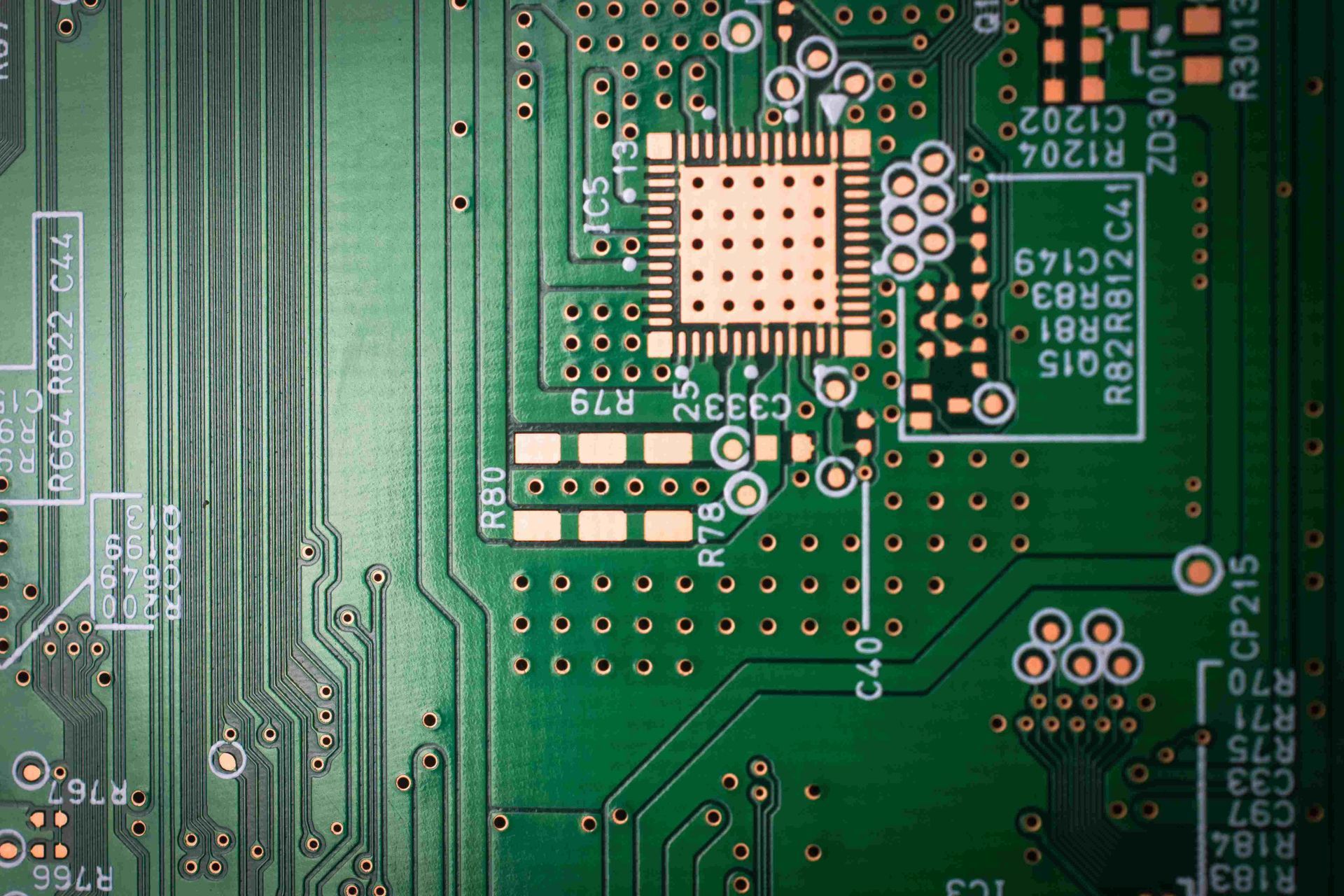

PTH Assembly, also known as Printed Through-Hole Assembly, is a type of electrical circuit board assembly in which components are connected to the board via holes. When the components must be securely soldered onto the board and cannot be soldered using surface mount technology, this sort of assembly is utilised. It is also used when components must be positioned on both sides of a board.

PTH Assembly is a low-cost method of assembling components onto a board because it uses fewer tools and materials than other methods of assembly. It also provides additional freedom in component placement and arrangement.

Benefits of PTH Assembly

There are various advantages of adopting PTH Assembly for product development initiatives. Because the components are securely soldered onto the board and are less prone to fall away, this style of assembly is more trustworthy than others. It also provides additional freedom in component placement and arrangement. It is also a more cost-effective method of assembling components onto a board because it uses less equipment and materials than other methods of assembly.

PTH Assembly also enables components to be positioned on both sides of the board, resulting in more efficient products. It is also a time-saving method because it has fewer steps than other types of assembly and may be completed faster.

What You Need to Know About PTH Assembly

PTH Assembly is a dependable and cost-effective method of assembling components onto a board, but there are a few considerations when employing this sort of assembly. It necessitates the use of specialised tools and materials, as well as a certain amount of competence to ensure that the components are properly soldered to the board. Also, using the correct size of components for the board is critical, as components that are too large or too small may not fit properly.

It is also critical to utilise the proper solder for the components, as some may require lead-free solder or low-temperature solder. Furthermore, it is critical to verify that the board is appropriately insulated to avoid shorts or other issues.

Conclusion

PTH Assembly is an efficient method of assembling components onto a board. It is a low-cost and dependable approach to producing efficient products. It necessitates the use of specialised tools and materials, as well as a certain amount of competence to ensure that the components are properly soldered to the board. It is also critical to use the exact size components for the board as well as the suitable type of solder for the components.

If you are a product developer searching for a dependable means to swiftly and cost-effectively assemble components onto a board, PTH Assembly may be the ideal option.

M-Tek Assembly is a PCB manufacturer specialising in the production of low-cost, high-quality printed circuit boards and PTH assembly. We have a wealth of industry knowledge, and our experienced engineering staff will assist you through the entire process. Using M-Tek for printed circuit board repairs will also assist to conserve the environment. We have achieved a

net-zero carbon footprint by using electric vehicles, and for every circuit board we build, we plant a tree! Contact one of our SMT and PCB assembly experts today for assistance. Call

01189 455377 or follow us on

Twitter to learn more about our services.

Recent Posts

Call Our Team

Want to find out more about our PCB assembly services? Speak to our team to find out how we can help you.

Join the Newsletter

We will get back to you as soon as possible

Please try again later