Flexible Printed Circuits

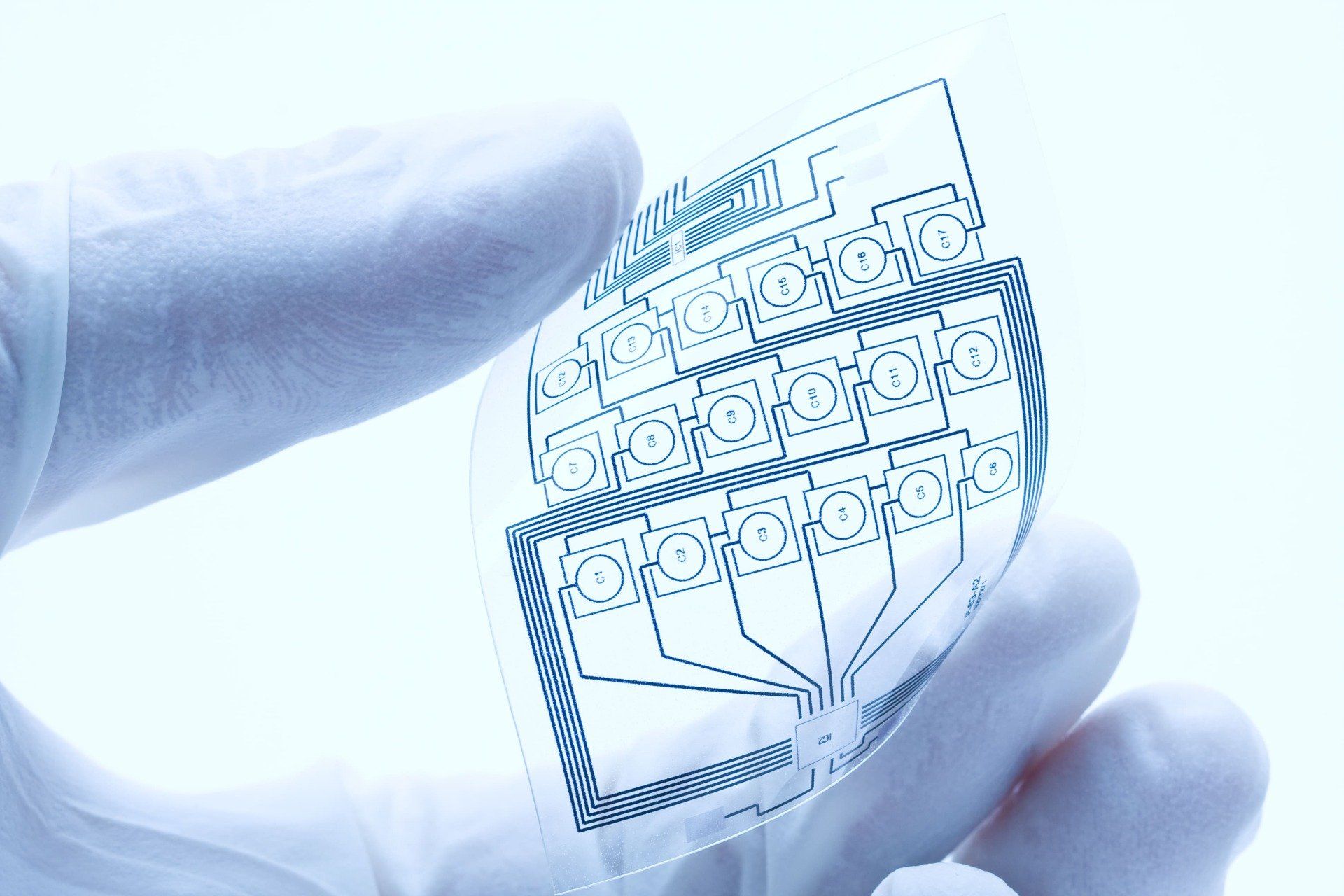

Flexible printed circuits(FPC) are circuit boards that can bend or twist. From this, we can gather that they can be distinguished by their flexible construction. Electronic engineers and designers use these properties in applications that require them. They are also known as flex circuits and are commonly used in small electrical applications.

Flexible substrates, such as polyimide, are used to create flexible printed circuits because this property distinguishes them. Another significant advantage of flexible printed circuits over printed circuit boards is improved heat dissipation. Because of this property, electronic devices that use it can last for a very long time in good condition. So, what's the difference between flexible printed circuit boards and traditional printed circuit boards (PCB)?

Flexible Circuits Assemblies Vs PCB Assemblies

Flexible Printed Circuits and Standard Printed Circuit Boards differ in several ways. It's worth noting that, while both have a similar electrical purpose, they have significant mechanical and structural differences. The first distinction between the two is that a flexible printed circuit can bend and twist, whereas a Printed Circuit Board cannot. Because of this distinction, the two require distinct manufacturing materials, processes, and designs. Based on the preceding assertion, consider the various materials used in the applications of flexible Printed Circuits and standard Printed Circuit Boards.

For a printed circuit board, the base layer must be rigid and typically reinforced by the glass. The most commonly used material in this case is FR4. The material used offers much-needed stability, thermal properties, and mechanical strength. However, it cannot bend. The base materials used for the flexible circuit, on the other hand, are mostly polyimide. The benefit of using this material is that it is an extremely flexible cable, but its ability to provide mechanical support is restricted. Its physical properties are also limited.

When it comes to adhesives, the demands for PCB are heavily weighted toward thermal and chemical properties. The primary reason for this is that they do not flex. A flexible printed circuit is not the same. Because it must bend, the adhesive used must allow for bending for the application to function properly. An adhesive designed for a flexible circuit must be capable of significant stretching. The bottom line is that a flexible printed circuit adhesive has distinct thermal, mechanical, and chemical properties than a printed circuit board adhesive.

Finally, we'll take a look at the copper film. There are two types of copper film. One is Electro Deposited, and the second is Rolled Annealed. Between both the Rolled Annealed has much more pliability and is thus the better choice for a flexible printed circuit application. However, despite its flexibility, Electro Deposited copper is primarily used in the manufacturing of printed circuit boards. The copper used has a significant impact on the performance of a flexible circuit.

What are the Different Flexible Circuit Boards?

There are several types of flex circuit boards. They are typically designed to meet a variety of configurations and quality standards. It's also worth noting that they're classified according to their layers. Let's look at the various types of flex circuit boards based on configurations and layers.

HDI Flexible Circuit Boards

High-density connection is a characteristic of these circuit boards. These are the printed circuit boards to choose from if you're seeking ones with better performance. In essence, they generate performance that is superior to that of standard flexible circuit boards. They include many elements and have sophisticated designs and construction, which is why they perform at a higher level. Additionally, compared to conventional substrates, HDI flexible printed circuit boards use thinner substrates. Both their performance and size are greatly improved by doing this.

Rigid-Flex PCBs

These particular printed circuit boards, as the name suggests, combine rigid and flexible printed circuit boards. A rigid-flex circuit board layout typically consists of several hard circuits connected by flexible circuits. The benefit of hybrid circuits is that they enable designers to increase the functionality of circuits. It's crucial to emphasise how useful the stiff portions are for mounting various parts, such as connectors and chassis. In contrast, the flexible parts are utilised to guarantee vibration-free resistance.

Flexible Circuit Boards Classification Based on Layers

Single-Sided Flexible Circuit Boards: This is one of the most fundamental types of flexible circuit boards based on layers. It is made up of a single layer of polyimide film. It also has a thin layer of copper on it.

Double-Sided Flexible Circuit Boards:

On either side of the polyimide layer, these circuit boards have a double layer of conductors.

Multi-Layered Flexible Circuits: This circuit is made up of both double-sided and single-sided flexible circuits.

Based on the above types of flexible circuit boards, it is clear that engineers and designers have a broader range of options for various applications. This flexibility is what makes flexible circuit boards so useful.

By selecting M-Tek Assembly Ltd for your flexible circuit board assembly, you will also be contributing to environmental preservation. We have achieved a net-zero carbon footprint by using electric vehicles, and we plant a tree for every circuit board we build! Please contact one of our SMT and PCB assembly experts for assistance right away. To learn more about our services, call 01189 455377 or follow us on Twitter.

Recent Posts

Call Our Team

Want to find out more about our PCB assembly services? Speak to our team to find out how we can help you.

Join the Newsletter

We will get back to you as soon as possible

Please try again later