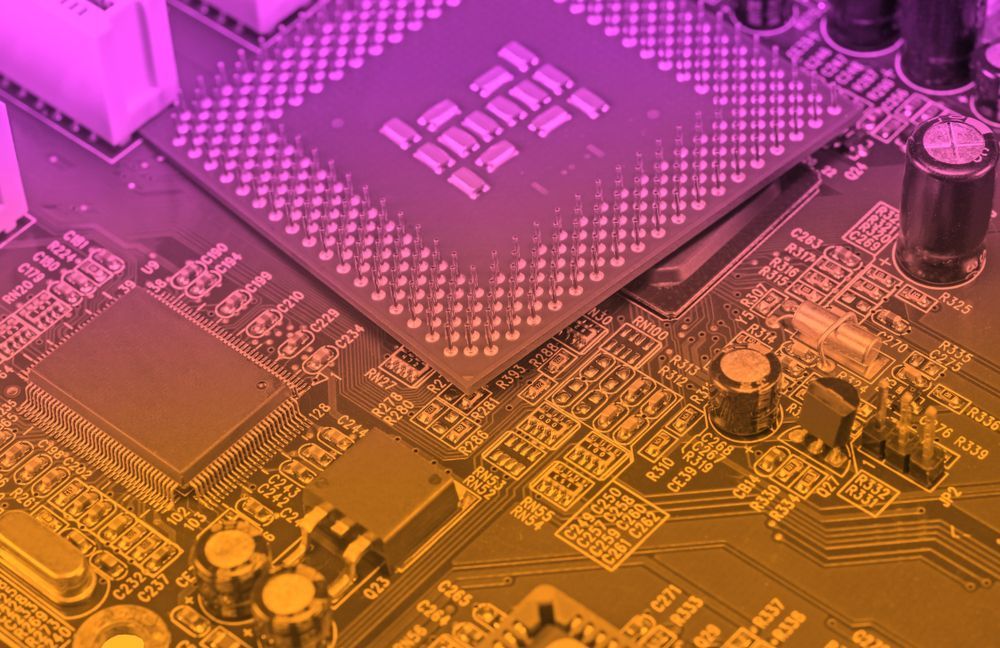

Printed Circuit Boards (PCBS) are the backbone of almost all electronic devices.

They are flat boards made of non-conductive materials, with conductive pathways etched onto their surfaces, connecting various components like resistors, capacitors, transistors, and integrated circuits. These pathways ensure that the components can communicate and work together seamlessly.

PCB Designs: What are miniature PCBs?

Miniature PCBs, as the name suggests, are much smaller than normal PCBs.

They are designed to occupy minimal space while packing a multitude of functionalities. The miniaturisation of PCBs allows electronics manufacturers to create compact and lightweight products that offer improved capabilities compared to larger PCBs.

Why Are People Making Miniature PCBs?

There are several reasons behind people making miniature printed circuit boards. This includes:

Portability: The era of bulky gadgets is gradually fading away. Consumers now prefer portable devices that can easily fit in their pockets or on their wrists. Miniature PCBs enable the creation of sleek and lightweight electronics that are easy to carry around.

Wearable Technology: The advent of wearable technology, such as smartwatches, fitness trackers, and smart clothing, requires compact PCBs that can seamlessly integrate into these wearable devices.

IoT Devices: The Internet of Things (IoT) has revolutionised the way we interact with our surroundings. IoT devices require tiny PCBs that can be embedded in various objects, connecting them to the internet and enabling data exchange.

Space Constraints: In industries like aerospace, automotive, and medical devices, space is often limited. Miniature PCBs allow manufacturers to optimise the use of available space while maintaining high functionality.

Energy Efficiency: Miniature PCBs often require less power due to their reduced size and optimised designs, making them ideal for battery-powered devices.

Cost Efficiency: Smaller PCBs use fewer materials and require less manufacturing time, leading to cost savings during production.

Are Miniature PCBs Effective?

The effectiveness of miniature PCBs depends on the specific application and design considerations.

However, designing and manufacturing miniature PCBs can be challenging. The high component density makes heat dissipation more difficult, potentially leading to overheating issues.

Moreover, the smaller size requires precise engineering to ensure that all connections are reliable and avoid signal interference.

Final Thoughts

In conclusion, miniature PCBs are becoming increasingly prevalent in today's electronics landscape due to their portability, versatility, and improved performance.

They have opened up new possibilities for wearable technology, IoT devices, and other space-constrained applications.

While they require careful design and consideration, their potential benefits make them a valuable tool for creating compact and efficient electronic devices.

As technology continues to advance, we can expect to see even more innovative uses of miniature PCBs in the electronics of tomorrow.

Call

01189 455377 or follow us on

Twitter to learn more about our products and services.

Recent Posts

Call Our Team

Want to find out more about our PCB assembly services? Speak to our team to find out how we can help you.

Join the Newsletter

We will get back to you as soon as possible

Please try again later