What is Turnkey Product Assembly?

Have you ever wondered what turnkey product assembly is and how it can help your business? Many business owners and entrepreneurs are now turning to turnkey product assembly as a way to save time, reduce costs, and produce products more efficiently. In this article, we will explain what turnkey product assembly is and how it can benefit your business.

What is Turnkey Product Assembly?

Turnkey product assembly is a process of producing products using outside vendors and specialised tools. This type of assembly usually involves outsourcing production to a third party that has the necessary expertise and resources to produce the product. This type of assembly eliminates the need for a business to invest in expensive machinery, tools, and manpower to produce its product.

The turnkey product assembly process starts with the vendor providing a detailed plan, drawings, and specifications for the product. The vendor then works closely with the business to ensure that the product is assembled correctly and to the highest standards. The vendor is also responsible for providing any necessary parts or materials to complete the assembly process.

Benefits of Turnkey Product Assembly

Turnkey product assembly offers many benefits to businesses. It can help reduce costs, save time, and increase production efficiency. Here are some of the advantages of turnkey product assembly:

- Reduced costs: By outsourcing production to a third-party vendor, businesses can save money on expensive machinery, tools, and manpower.

- Increased production efficiency: Turnkey product assembly is faster and more efficient than traditional manufacturing processes. This allows businesses to produce products more quickly and with higher quality.

- Expertise and resources: Vendors have the expertise and resources needed to produce high-quality products. This allows businesses to focus on other aspects of the business.

Things to Consider When Choosing a Turnkey Product Assembly Vendor

When choosing a turnkey product assembly vendor, it is important to consider their experience, quality of work, and pricing. It is also important to make sure that the vendor can meet your deadlines and provide the necessary parts and materials to complete the assembly process. It is also important to make sure that the vendor can provide the necessary customer service and technical support.

It is also important to do research on the vendor and read reviews from other businesses that have used their services. This will help you get a better understanding of the quality of the vendor's work and customer service.

Conclusion

Turnkey product assembly is a great way for businesses to save time, reduce costs, and increase production efficiency. It is important to do research and choose a vendor that has the necessary experience, resources, and pricing to meet your needs. With the right vendor, turnkey product assembly can be a great way to produce high-quality products quickly and efficiently.

If you are considering turnkey product assembly for your business, we recommend doing research and speaking to vendors to find the best fit for your needs. With the right vendor, turnkey product assembly can help your business increase efficiency and save money.

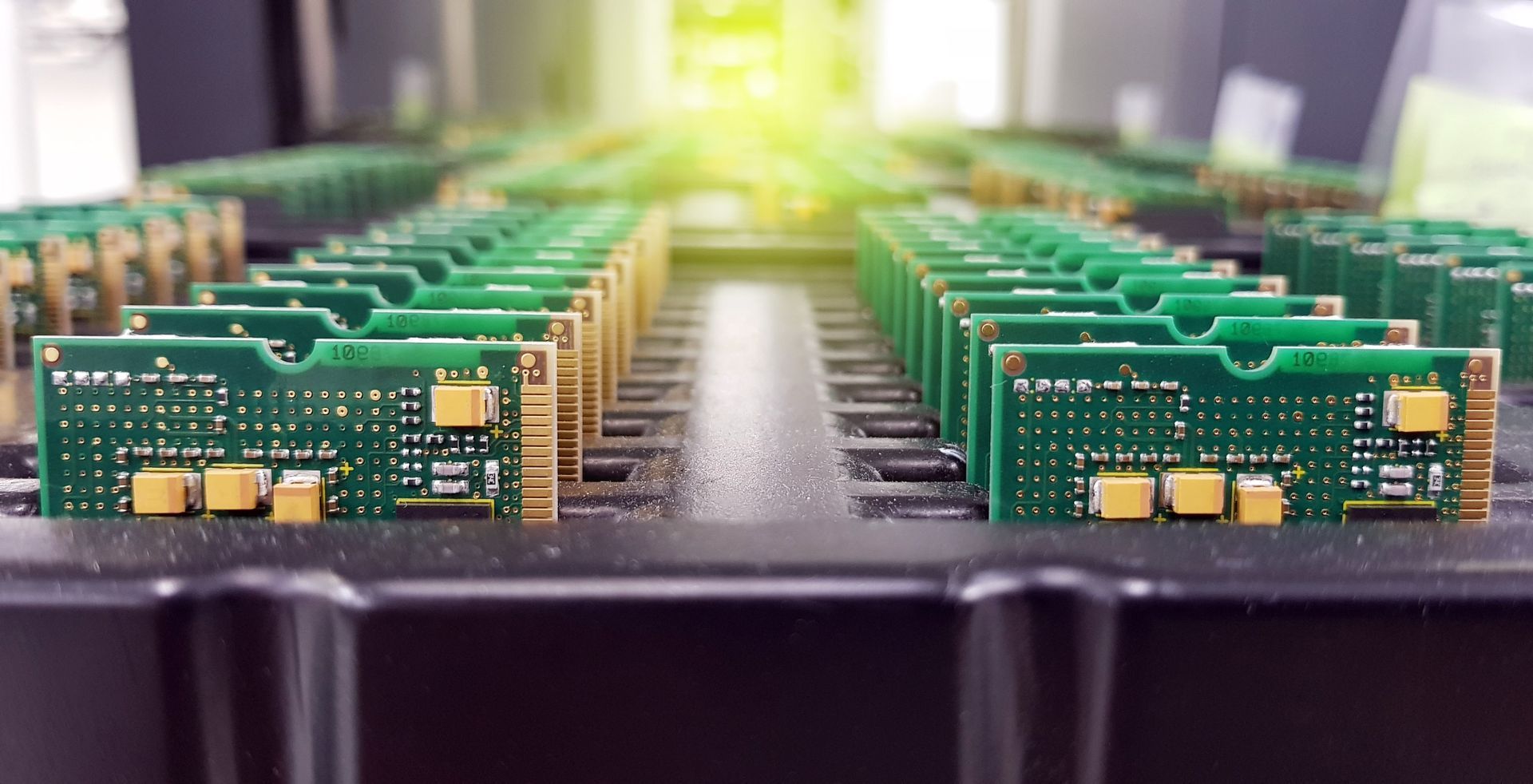

At M-Tek Assembly, we offer a wide range of services, including engineering support, testing setups and equipment, prototyping, software development, programming, and product support. Our printed circuit board

turnkey product assembly services will help you stay competitive in your industry and boost your overall efficiency with high-quality products at an affordable price. To begin your project,

get in touch with us!