Printed circuit boards (PCBs) are becoming more important in various industries. They are utilised for a number of reasons, including for medical devices, in the marine and engineering industries and throughout businesses of all sizes. Therefore, it is vital to improve the efficiency of the production line as much as possible. Enter X-ray inspections.

Let’s have a look at the benefits X-ray inspections on PCBs can have and how they can benefit your company.

Identify Errors in Landing Patterns

Landing patterns of particular pieces on the board are one of the faults that frequently happen when installing components on PCBs. The issue of getting the landing pattern incorrectly arises if the components that need to be built on the board are not among those found in the library of frequently used SMD components.

Creating a schematic of the newly added component and its landing pattern on the board is frequently a need for the design engineer. When this schematic is absent, it may be difficult to detect errors in the landing pattern through eye inspection. X-ray inspections enable the simple detection of a bad landing pattern for a component that has been mounted on the board.

Sees Through BGAs

Thanks to Ball Grid Array (BGA), PCB assembly can include smaller and more precise electronic component arrangements. Yet, this has its limitations. Particularly in terms of quality control and inspections. Components fitted using the BGA reballing technique are frequently crammed closely together on the board with little to no room between them. Therefore, inspectors may not be able to identify flaws in the printed circuit board.

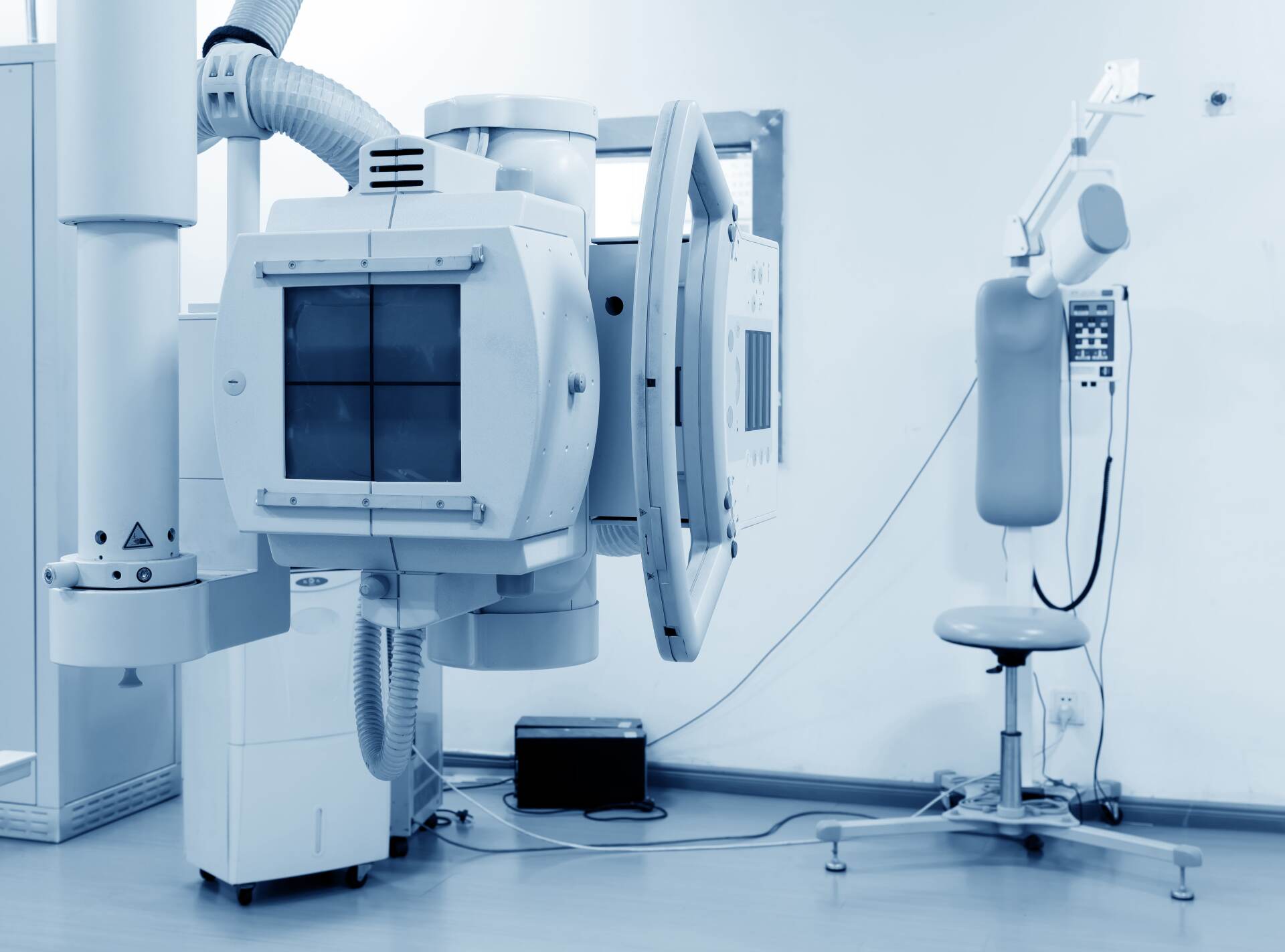

With its X-rays penetrating the BGA assembly, a

PCB X-ray machine is frequently the most effective way to evaluate the quality of the components and the board connection. The inspector may view individual components in the PCB X-ray inspections, with the machine producing images to spot any issues.

Improves Safety and Efficiency

As X-ray inspections are non-destructive and non-intrusive, this improves the efficiency of of the inspections. This means samples do not have to be made that are sent away for an external inspection. There are no damages and compared to other inspection methods, is a much faster means for the production line.

Identify Solder Voids

Soldering refers to the connecting of the printed circuit board and its electronic components. Soldering mistakes will result in defective connections, problems with product quality and even health and safety risks. To avoid these issues, inspectors will look for solder voids which may lead to any of these problems. However, as aforementioned, these components may be tightly packed together, due to BGA. So, this can lead to problems identifying any soldering issues with a visual inspection.

Instead, PCB X-ray inspections are a much more productive alternative. The PCB X-ray machine is frequently chosen as the best approach to this problem since it enables inspectors to precisely identify solder gaps that may result in a connection or product of poor quality.

Quick Feedback

Manufacturers can improve product quality and promote a favourable brand image by taking remedial action in response to quick feedback throughout the early stages of product development.

About M-TEK

M-Tek Assembly Ltd. is one of the leading electronic manufacturers in the UK. Our operations and services span globally, providing for a variety of businesses in industries such as marine, telecommunications and security. We utilise various services to ensure cost-effective and time-saving production lines, without compromising the quality of the products. This includes capabilities such as rapid prototyping, box build assembly and X-ray inspections of PCBs.

For more information, or to receive a quote, call us at 01189 455 377 and speak to one of our experts today. Make sure to

follow us on Twitter to stay up to date with our latest services.