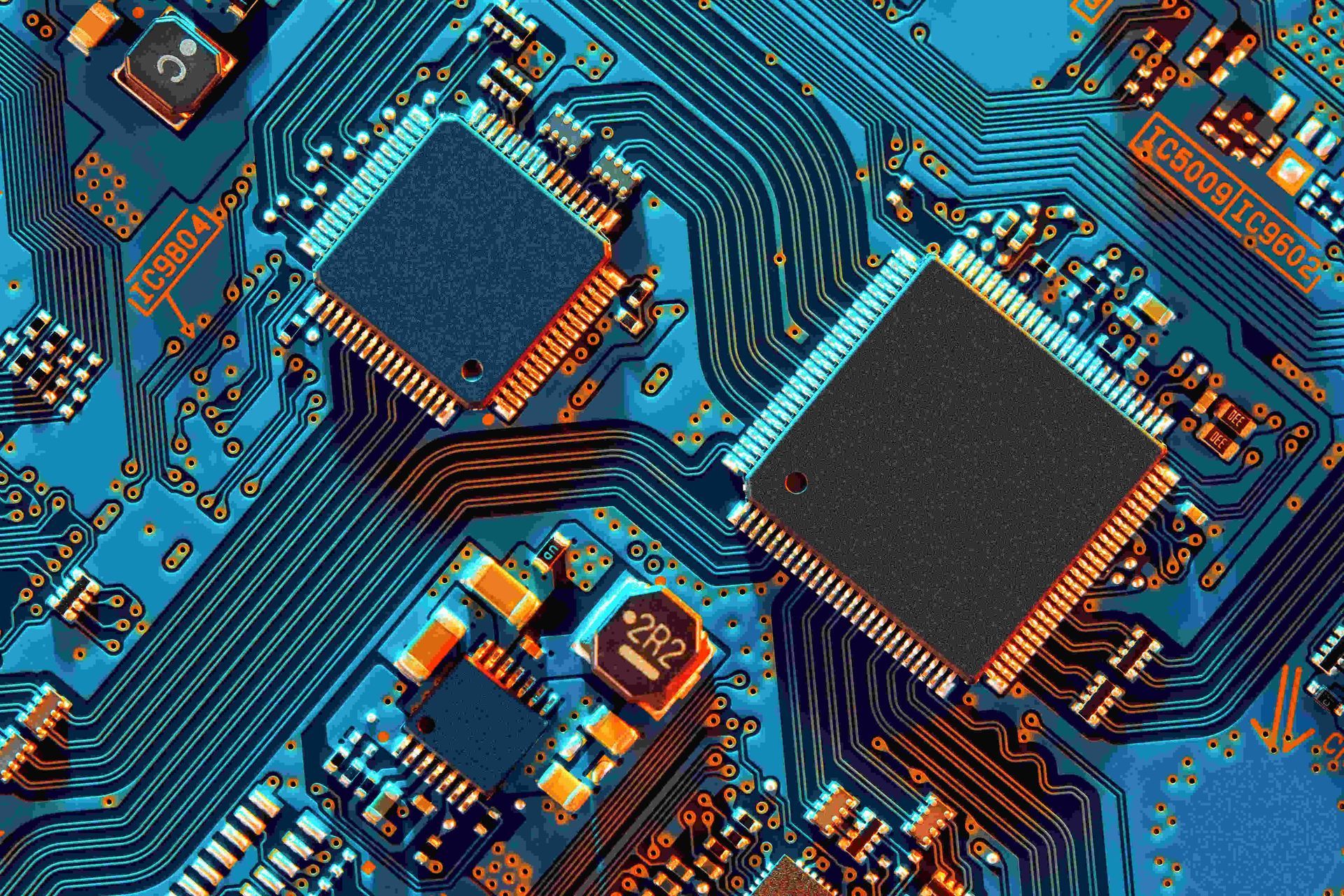

Circuit boards are a crucial part of electronic equipment.

They serve as the backbone for the electrical connections and components that make up the device. However, circuit boards are not immune to defects, and these defects can cause significant problems in the performance of electronic devices. In this article, we will discuss the most common circuit board defects and how to fix them.

Short Circuits

Short circuits occur when two or more conductive traces on a circuit board touch each other, causing a direct path for current to flow between them. This can cause the device to malfunction, overheat, or even catch fire. Short circuits can occur due to a variety of reasons, including design flaws, manufacturing errors, and component failure.

To fix a short circuit, the first step is to locate the source of the problem. This can be done by visually inspecting the board for any signs of damage or by using a multimeter to check for continuity between different points on the board. Once the source of the short circuit is identified, the next step is to isolate the affected area by cutting the trace or removing the component causing the short. A jumper wire can then be used to reconnect the circuit at the correct point.

Open Circuits

Open circuits occur when there is a break in the electrical connection between two points on the circuit board. This can be caused by a faulty trace, a damaged component, or poor soldering.

To fix an open circuit, the first step is to identify the location of the break by visually inspecting the board or using a multimeter to check for continuity. Once the break is identified, the damaged trace or component can be replaced, or a jumper wire can be used to bridge the gap.

Soldering Issues

Soldering is the process of joining components to the circuit board using a molten metal alloy. Poor soldering can result in a weak connection or even no connection at all. This can cause intermittent or permanent failures in the device.

To fix soldering issues, the first step is to visually inspect the solder joints for any signs of damage, such as cold joints or solder bridges. The joints can then be reworked by reheating them with a soldering iron and adding more solder if necessary.

Component Failure

Electronic components can fail for a variety of reasons, including manufacturing defects, age, or exposure to harsh environmental conditions. Component failure can cause a wide range of problems, from minor glitches to complete device failure.

To fix a failed component, the first step is to identify the faulty component using a multimeter or other testing equipment. Once the component is identified, it can be replaced with a new one.

ESD Damage

Electrostatic discharge (ESD) is a sudden, high-voltage surge of electric current that can damage electronic components. ESD can occur when two objects with different electrical charges come into contact with each other or when a charged object comes into contact with an uncharged object.

To fix ESD damage, the first step is to identify the affected components by visually inspecting the board or using a multimeter to check for continuity. The damaged components can then be replaced with new ones.

Final Thoughts

In conclusion, circuit board defects can cause significant problems in electronic devices. However, with the right tools and knowledge, most circuit board defects can be fixed. The key is to identify the source of the problem and take the necessary steps to correct it.

M-Tek Assembly

At M-Tek Assembly we have decades of experience. We have achieved a net-zero carbon footprint by using EVs, and for every printed circuit board we build, we plant a tree.

Contact one of our SMT and PCB assembly professionals today for assistance. Call

01189 455377 or follow us on

Twitter to learn more about our services, including vacuum casting.

Recent Posts

Call Our Team

Want to find out more about our PCB assembly services? Speak to our team to find out how we can help you.

Join the Newsletter

We will get back to you as soon as possible

Please try again later