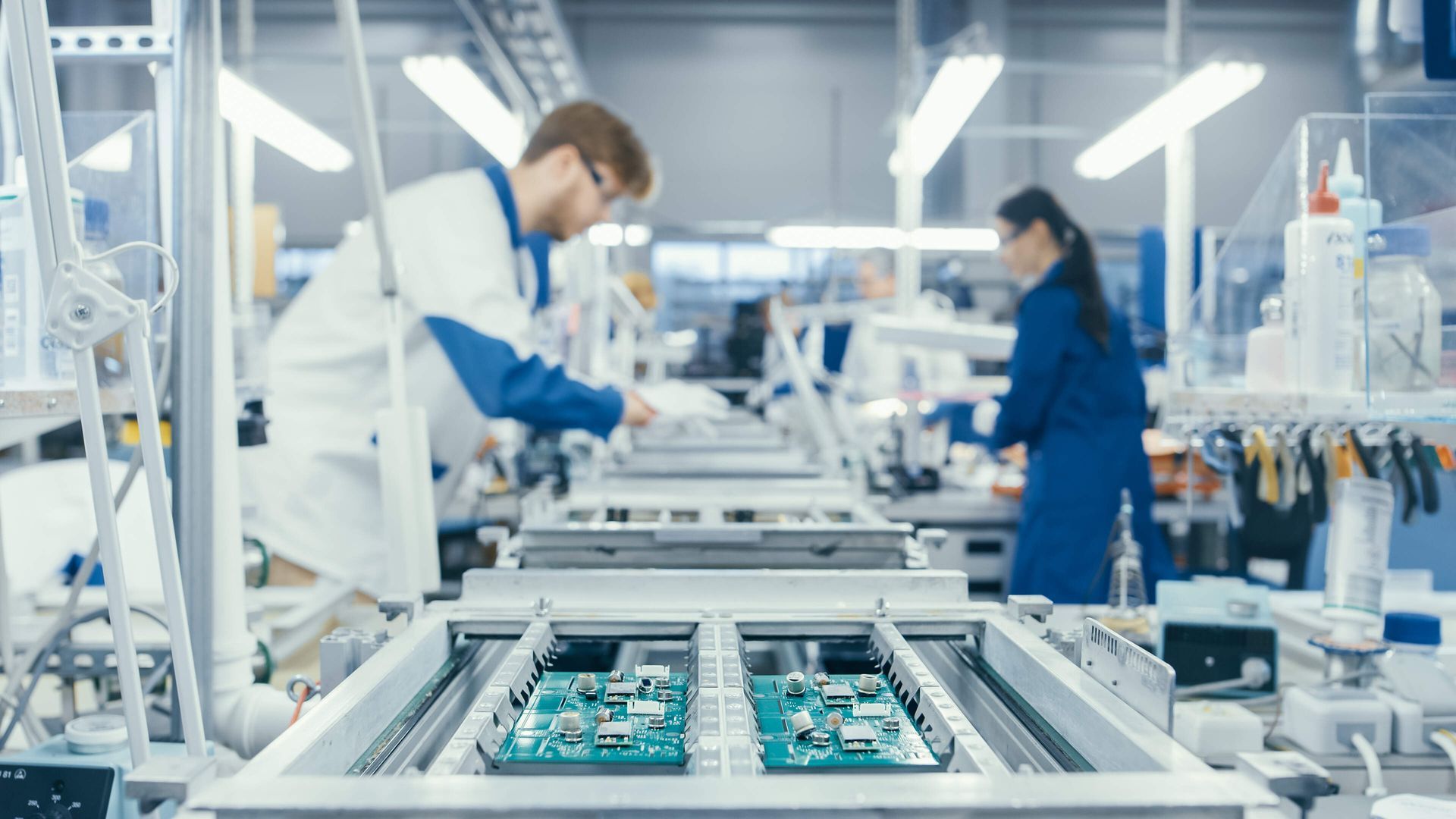

PCB assembling involves attaching electronic components to a PCB board to create a functional device. When it comes to PCB assembly, companies have the option of assembling in-house or outsourcing the process. Both options have their advantages and disadvantages, and in this article, we'll explore them.

Advantages of In-House PCB Assembly

When assembling PCBs in-house, a company has complete

control over the process. They can decide on the materials to be used, the equipment, and the quality control measures. This control allows companies to ensure that the assembly meets their desired specifications and standards.

In-house assembly allows for a

faster turnaround time as there are no delays in sending the PCBs to an outside vendor. The company can start assembling the PCBs as soon as they receive them, which can be critical for time-sensitive projects.

Although initial setup costs can be high, an in-house assembly can

save money in the long run. Outsourcing can be expensive, and companies must pay shipping and other fees. In-house assembly eliminates these costs, and companies can save money by reusing materials and reducing scrap waste.

In-house assembly allows companies to be

more flexible and agile when it comes to their production process. They can quickly make changes to their assembly process and respond to changes in demand without relying on an outside vendor.

Disadvantages of In-House PCB Assembly

Setting up an in-house assembly line requires a

significant investment in equipment and infrastructure. Companies need to purchase specialised machinery, hire skilled workers, and ensure that they have a clean and controlled environment.

In-house assembly requires a

specialised skill set that not all companies may possess. Hiring skilled workers can be expensive and time-consuming, and companies must invest in training and development to ensure that their workers have the necessary expertise.

Quality control challenges. In-house assembly can be challenging when it comes to quality control. Companies must have the necessary equipment and processes to ensure that the PCBs are assembled correctly and to a high standard.

Advantages of Outsourcing PCB Assembly

Cost-effective. Outsourcing can be cost-effective, especially for small and medium-sized companies that do not have the resources to set up an in-house assembly line. Outsourcing eliminates the need for costly equipment and infrastructure investments, and companies can benefit from economies of scale.

Expertise. Outsourcing allows companies to benefit from the expertise of specialised vendors. PCB assembly companies have the necessary equipment, processes, and skilled workers to ensure that the assembly is done to a high standard.

Scalability. Outsourcing allows companies to scale up or down their production as needed. They can quickly adjust their production levels without having to invest in additional equipment or hire new workers.

Disadvantages of Outsourcing PCB Assembly

Lack of control. Outsourcing gives companies less control over the assembly process. They cannot make changes to the assembly process without relying on the vendor.

Longer turnaround time. Outsourcing can lead to longer turnaround times as companies must wait for the vendor to complete the assembly process and return the finished PCBs.

Quality control issues. Quality control can be a challenge when outsourcing PCB assembly. Companies must rely on the vendor to ensure that the assembly is done to a high standard.

Conclusion

In conclusion, both in-house and outsourcing PCB assembly have their advantages and disadvantages. Companies must carefully evaluate their production needs and goals to determine which option is best for them. The in-house assembly provides greater control, faster turnaround times, and flexibility, but requires significant upfront investment and specialised expertise.

M-Tek Assembly

At M-Tek Assembly we have decades of experience. We have achieved a net-zero carbon footprint by using EVs, and for every printed circuit board we build, we plant a tree.

Contact one of our SMT and PCB assembly professionals today for assistance. Call

01189 455377 or follow us on

Twitter to learn more about our services, including vacuum casting.