Types of Printed Circuit Boards

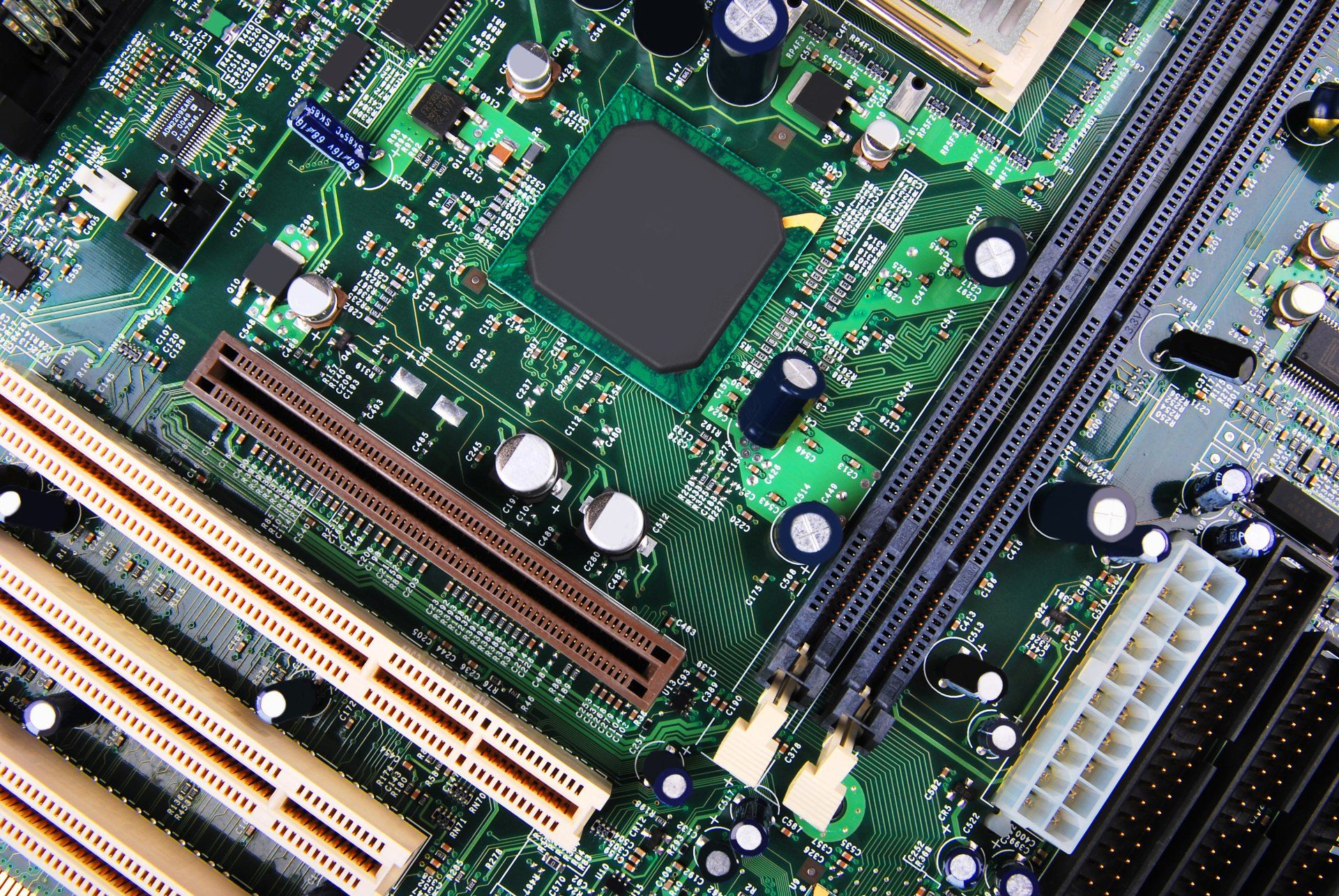

Printed Circuit Boards (PCBs) are separate boards that use conductive rails to mechanically support and electrically link electronic components. They are the foundation of every piece of hardware or electrical equipment. So, which type do you need? Well, sometimes, these circuit boards are made specifically to fit inside various kinds of devices.

Find out the different types of circuit boards here and what devices they can help.

Single-Layer

The simplest and least expensive type of printed circuit board is the single-sided PCB. These kinds of PCBs only have one copper layer and one glass layer that serves as the foundation substrate. Electronic component holes are typically not plate-through holes. On one side is the layout for the electronic parts, and on the other is the conductive circuit.

One of the benefits of this printed circuit board is that they are much cheaper to manufacture than other types and are easier to design. Single-layer PCBs are typically used in devices such as:

Home appliances- Mobile phones

- Radios

Double-Layer

For double-sided PCBs, there is a single layer of the base substrate and a conductive layer on both sides. The electronic components are then soldered together and can have through-hole components and SMD attached on either side.

As they are manufactured on both sides, double-layer PCBs have an increase in use and flexibility compared to single-layered printed circuit boards. With more space, there is more complex circuitry and consequently, a reduction in production cost. Double-layer PCBs can be used for:

LED lights- Vending machines

- Industrial controls

Multi-Layer

A printed circuit board having more than two layers is called a multilayer PCB. These kinds of PCBs must contain a minimum of 3 copper or conductor-filled conducting layers. Copper-plated holes connect one layer to the next. The top and bottom layers are used to build all of the active and passive electronic components. Every single inner stacked layer is intended for routing.

Multi-layer printed circuit boards offer high and detailed design flexibility and are vital for high-speed circuits. These can be used for devices like:

Computers- Heart monitors

- Mobile phones

Rigid PCB

The most conventional type of board in the PCB industry is a rigid circuit board. They are still widely employed in numerous things that people buy every day and are still very popular.

Circuit boards known as rigid PCBs have robust, inflexible structures that prevent them from being bent or deformed. A substrate layer, a copper layer, a solder mask layer, and a silkscreen layer are just a few of the various layers that make them up. These layers are adhered to one another by heat and glue. Devices that use these include:

Pacemakers- Digital cameras

- Smart devices

Flexible Printed Circuit Boards

The name gives it away. Flexible PCBs relieve their users of the stress of weight and space that rigid printed circuit boards have. Instead, these PCBs can be moulded into various shapes and bent at difficult angles. This allows for improved functionality on your circuit board. Find out more about flexible printed circuit boards here on our previous blog.

These printed circuit boards can come in either single, double or multi-layered boards and helps decrease the size. Various devices can implement these, such as:

Airbag systems- Robotic arms

- Hearing aids

M-Tek Assembly Ltd.

By selecting M-Tek, for your printed circuit boards, you will also be contributing to environmental preservation. We have achieved a net-zero carbon footprint by using electric vehicles and we plant a tree for every circuit board we build!

Please contact one of our SMT and PCB assembly experts for assistance right away. To learn more about our services, call 01189 455377 or

follow us on Twitter.

Recent Posts

Call Our Team

Want to find out more about our PCB assembly services? Speak to our team to find out how we can help you.

Join the Newsletter

We will get back to you as soon as possible

Please try again later