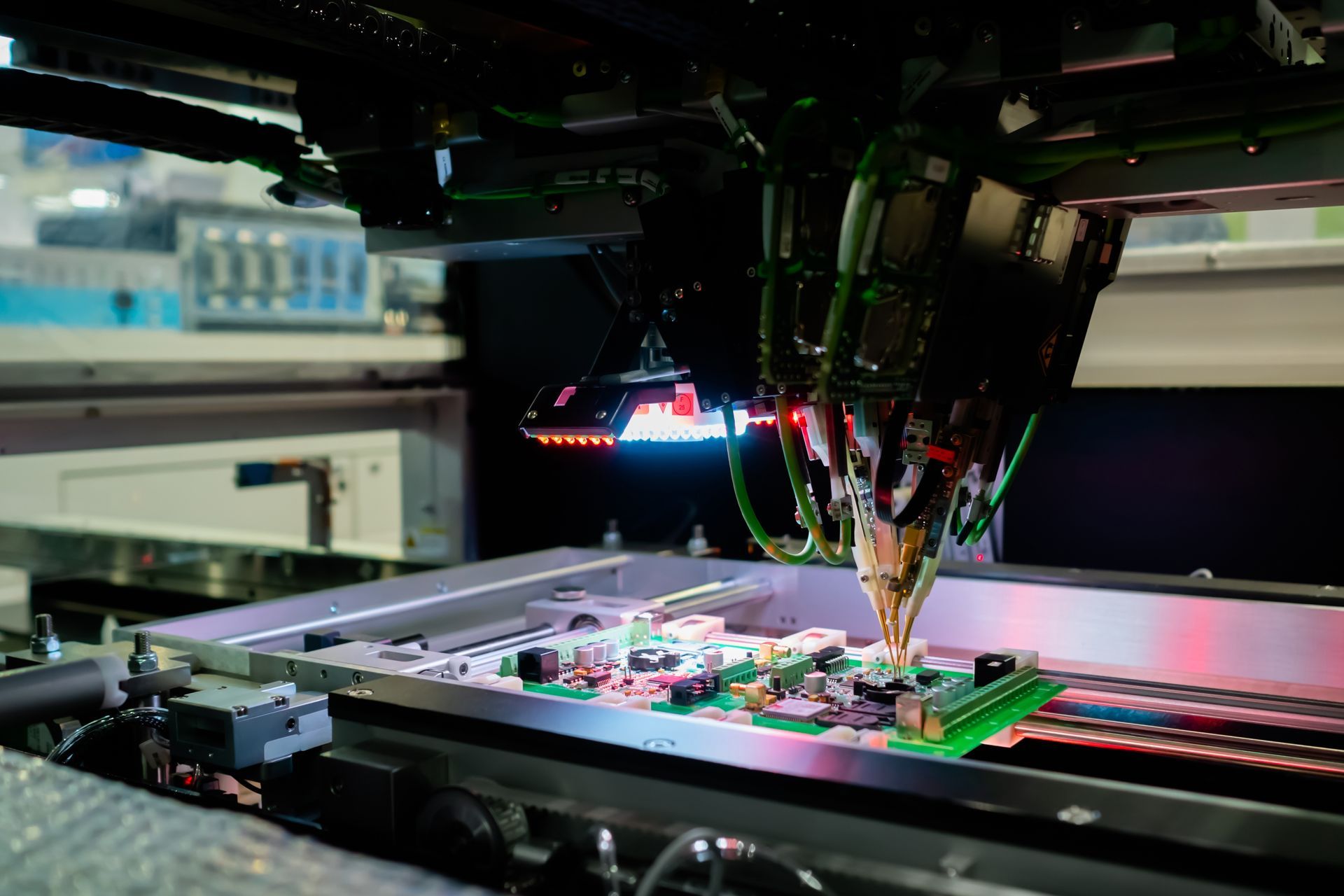

Flying Probe testing is a method of testing printed circuit boards (PCBs) that uses a specialised testing instrument to physically contact and test the electrical connections on the board. Unlike traditional in-circuit testing methods, which require a separate fixture for each test point, flying probe testing uses probes that can be moved and repositioned to test different points on the board. This allows for more flexible and efficient testing of PCBs, especially for prototypes, low-volume production runs, and complex boards.

What are the Principles of Flying Probe Testing?

The primary premise of flying probe testing is to make electrical contact with the test spots on the board and measure electrical properties like resistance, capacitance, and inductance. The probes are linked to a mechanical arm that can move and position itself to make contact with the test sites. The arm is controlled by specialised testing software, which coordinates probe movement and performs electrical tests.

What are the Benefits of Flying Probe Testing?

One of the major benefits of flying probe testing is its ability to test complex and irregularly shaped boards. Unlike traditional in-circuit testing methods, which require a separate fixture for each test point, flying probe testing can be used to test any point on the board, regardless of its shape or size. This makes it an ideal method for testing prototypes, low-volume production runs, and complex boards, where traditional testing methods may be impractical or cost-prohibitive.

Another advantage of using flying probe testing is that it can test boards rapidly and efficiently. When compared to traditional in-circuit testing methods, the probes may be moved and positioned quickly, allowing for speedier testing timeframes. This increased speed and efficiency are particularly advantageous for prototypes and low-volume production runs when time and cost are frequently crucial issues.

Flying probe testing is also more accurate and reliable than standard in-circuit testing procedures. Flying probe testing reduces the possibility of measurement mistakes that can occur with standard testing methods such as fixtures or bed-of-nails testing by physically contacting the test spots on the board. Flying probe testing is a key technique for ensuring the quality and performance of PCBs due to their accuracy and dependability.

Flying probe testing is a significant tool for research and development in addition to its benefits for evaluating PCBs. Flying probe testing allows engineers and technicians to optimise the design of new boards and improve their performance by providing precise information about the electrical connections on the board.

What Challenges Does Flying Probe Testing Face?

The cost and complexity of the equipment and software utilised in flying probe testing are one of the issues. Flying probe testers are often more expensive than ordinary in-circuit testers, and their operation necessitates specialised training and skill. Furthermore, flying probe testing necessitates the use of specialised software and algorithms to coordinate probe movement and conduct electrical tests.

Another difficulty with flying probe testing is evaluating high-density boards. The size and flexibility of the probes on flying probe testers limit their ability to test high-density boards with closely spaced test spots. This may need the use of additional probes, increasing the expense and complexity of the testing process.

Things to Consider

To summarise, flying probe testing is a way of evaluating printed circuit boards that offer greater flexibility, efficiency, precision, and dependability than traditional in-circuit testing methods. Its capacity to test complicated and irregularly shaped boards while also providing precise information on the electrical connections on the board makes it a valuable tool for quality control, reliability assessment, and R&D. Despite its drawbacks, such as the high cost and complexity of the equipment and software utilised, as well as the difficulty of evaluating high-density boards, flying probe testing is becoming a more popular way of testing PCBs.

How Can M-Tek Assembly Help?

Since 1996, at M-TEK, we have continuously delivered high-quality printed circuit boards and other electronic manufacturing services to a variety of industries. We employ various cost-effective and time-saving methods, including box-build assembly and flying probe testing. Get in touch with one of our experts for help with your SMT and PCB assembly today. Call us on 01189 455377, or follow us on Twitter to stay up to date with our services.

Recent Posts

Call Our Team

Want to find out more about our PCB assembly services? Speak to our team to find out how we can help you.

Join the Newsletter

We will get back to you as soon as possible

Please try again later