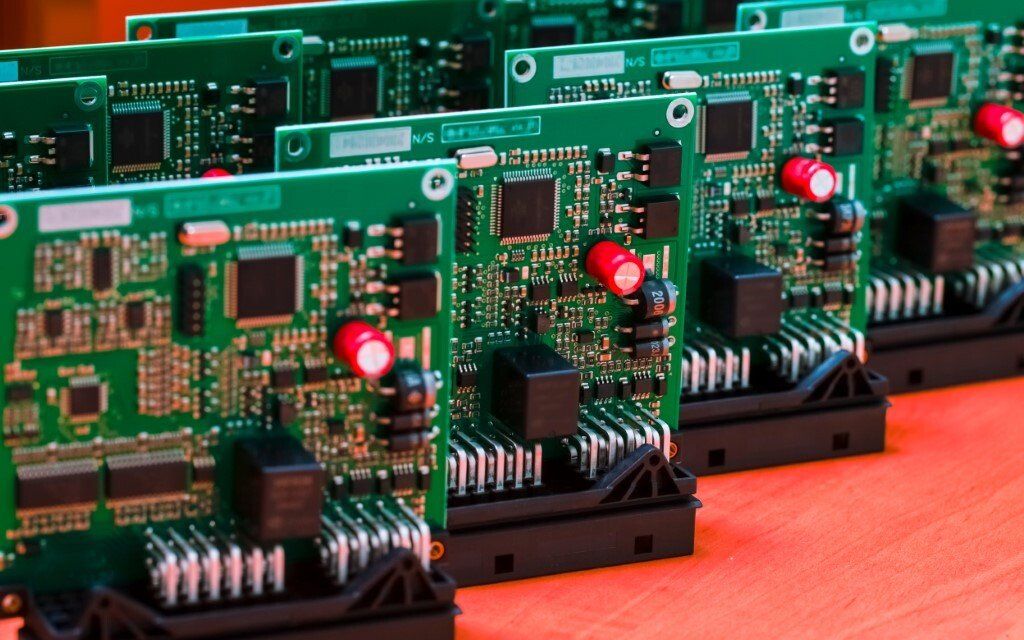

PCB batch production is a process in which a large number of printed circuit boards (PCBs) are manufactured at once, rather than producing them individually. This method is often used in the electronics industry when there is a high demand for a particular PCB design or when the cost of producing PCBs in smaller quantities becomes too high.

What are the Benefits of PCB Batch Production?

There are several benefits to using batch production for PCB manufacturing. One of the main advantages is cost savings. By producing a large number of PCBs at once, the manufacturer can take advantage of economies of scale and reduce the per-unit cost of production. This can be particularly beneficial for companies that require a large number of PCBs for their products.

Another advantage of batch production is that it allows for more efficient production processes. When producing PCBs in large quantities, the manufacturer can set up specialised equipment and processes that are optimised for high-volume production. This can lead to higher production speeds and improved quality control, as there is less need to switch between different production runs or products.

What is the PCB Batch Production Process?

There are several steps involved in the PCB batch production process. First, the PCB design must be finalised, and the necessary raw materials and components must be sourced. Next, the PCBs are fabricated using a process called photolithography, in which a circuit pattern is transferred onto a PCB using light-sensitive chemicals and a mask. The PCBs are then drilled, and the necessary holes are created using specialised drilling equipment.

Next, the PCBs are assembled by attaching the various components, such as resistors, capacitors, and integrated circuits, to the PCBs using soldering or other methods. After assembly, the PCBs undergo functional testing to ensure that they are functioning correctly. Finally, the PCBs are inspected and packaged for shipping.

Things to Take Away

Overall, batch production is a cost-effective and efficient way to manufacture PCBs, particularly when there is a high demand for a particular PCB design. By optimising production processes and taking advantage of economies of scale, manufacturers can produce high-quality PCBs at a lower cost and meet the needs of their customers.

By using M-Tek for your

PCB batch production, you will also be helping to save the environment. We have achieved a net-zero carbon footprint through the use of electric vehicles, and we plant a tree for every circuit board we build! Contact one of our experts today for assistance with your SMT and PCB assembly. To stay up to date on our services, call us at 01189 455377 or follow us on

Twitter.