Rapid Prototyping FAQs

At M-TEK, we provide a range of different services and capabilities for our customers. This includes rapid prototyping throughout the product development. But, what is rapid prototyping? Why is this process important? Find out below.

What is Rapid Prototyping?

The process, rapid prototyping, creates something that can then efficiently assess a product. This prototype is an early version of the product and enables various businesses and industries to evaluate and test the technology before mass production.

Generally speaking, rapid prototyping is a test. It’s to test whether the technology will be a success both functionally and with customers. This can be applied throughout all stages of product development. Find out why many in the industry use rapid prototyping

here on our previous blog.

How Does Rapid Prototyping Work?

Rapid prototyping involves primarily three steps. Firstly, the prototype must be created; which can either be high-fidelity that closely resembles the product, or low-fidelity where there is a distinct difference. Then, businesses must share the prototype with relevant users and stakeholders so they can review the technology. In this stage, any issues can be addressed and improved for customers.

Finally, based on the feedback, the company can then either repair their product to help improve their future designs.

What Are the Different Types?

There are various different types of rapid prototyping which can help businesses:

Stereolithography - an additive manufacturing process where UV light is applied to resin which solidifies.- Selective Laser Sintering (SLS) - involves using a high-power laser to fuse a powdered material.

- Direct Metal Laser Sintering (DMLS) - uses a laser to fuse powder into a solid material.

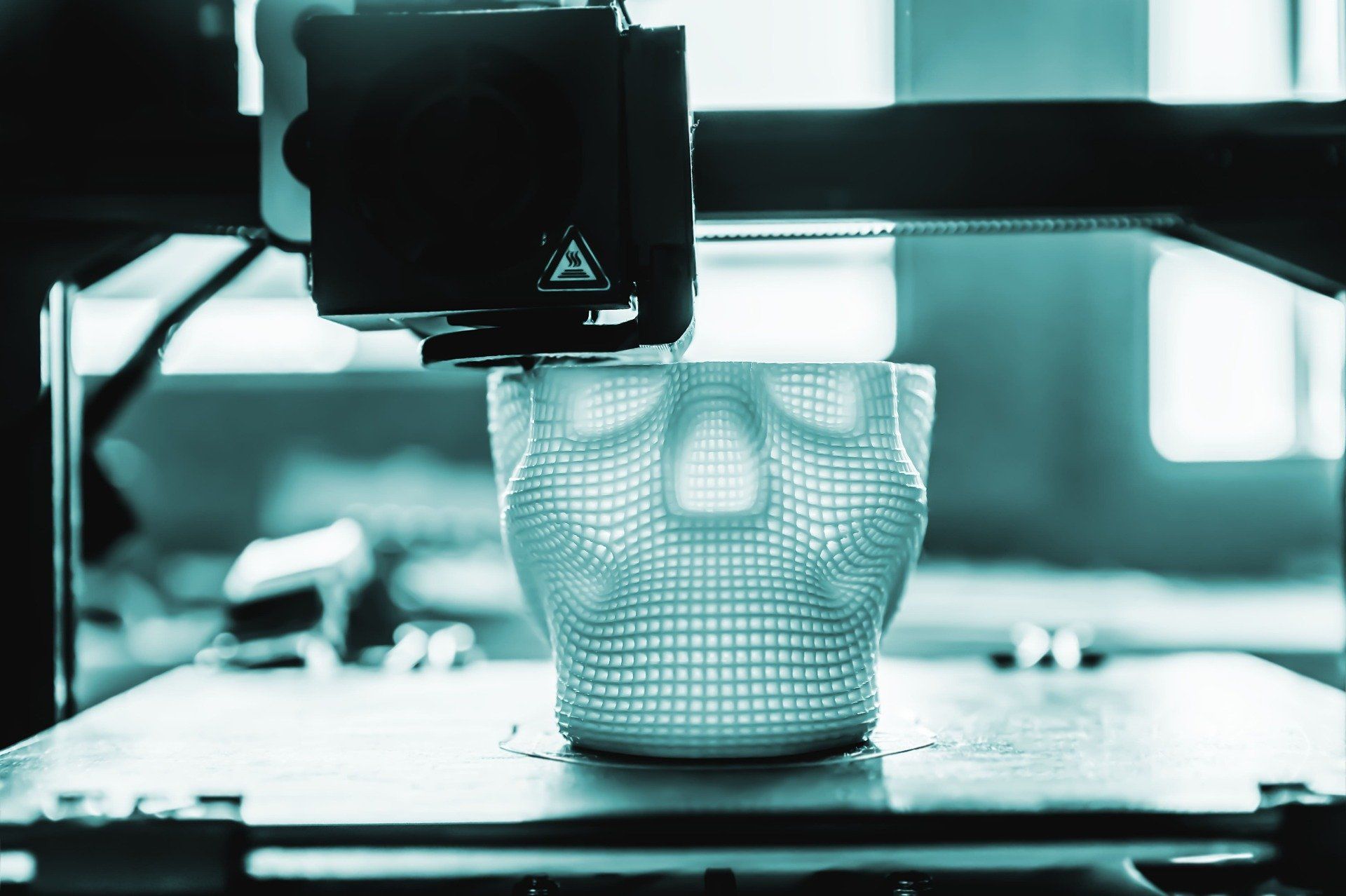

- Fused Deposition Modelling (FDM) - this is the least expensive method and is typically linked to 3D printing.

Is Rapid Prototyping the Same as 3D Printing?

Both rapid prototyping and 3D printing are extremely similar. Therefore, these two terms are often used interchangeably and confused with one another. Yet, they have their differences.

Whilst we have already discussed the process of rapid prototyping, where additive manufacturing allows you to produce prototypes much quicker, 3D printing is a method of this. 3D printing is a type of additive manufacturing, whereas rapid prototyping is an application.

The Benefits of Rapid Prototyping

This prototyping process is a very efficient method for producing minimal viable products in both time and money. With their quick turnaround rates for producing actual prototypes, 3D printers help developers reduce material waste, which lowers the cost of overall production.

Rapid prototyping enables businesses, designers, or engineers to quickly implement real-world proofs of concepts straight from CAD, allowing for low-risk concept testing. It can be considerably simpler to receive feedback and validation when an actual product is shown to stakeholders, investors, or customers rather than a concept.

M-TEK Assembly Ltd.

Established in 1996, M-TEK Assembly creates and manufactures printed circuit boards throughout the UK. Supplying to a variety of industries, PCB assembly has many benefits and we ensure that the manufacturing process runs smoothly and efficiently. We provide rapid prototyping services for both new product introduction (NPI) to mass production.

Fill in our online form here for our services. Or, call us on 01189 455377 and speak to one of our PCB experts today.