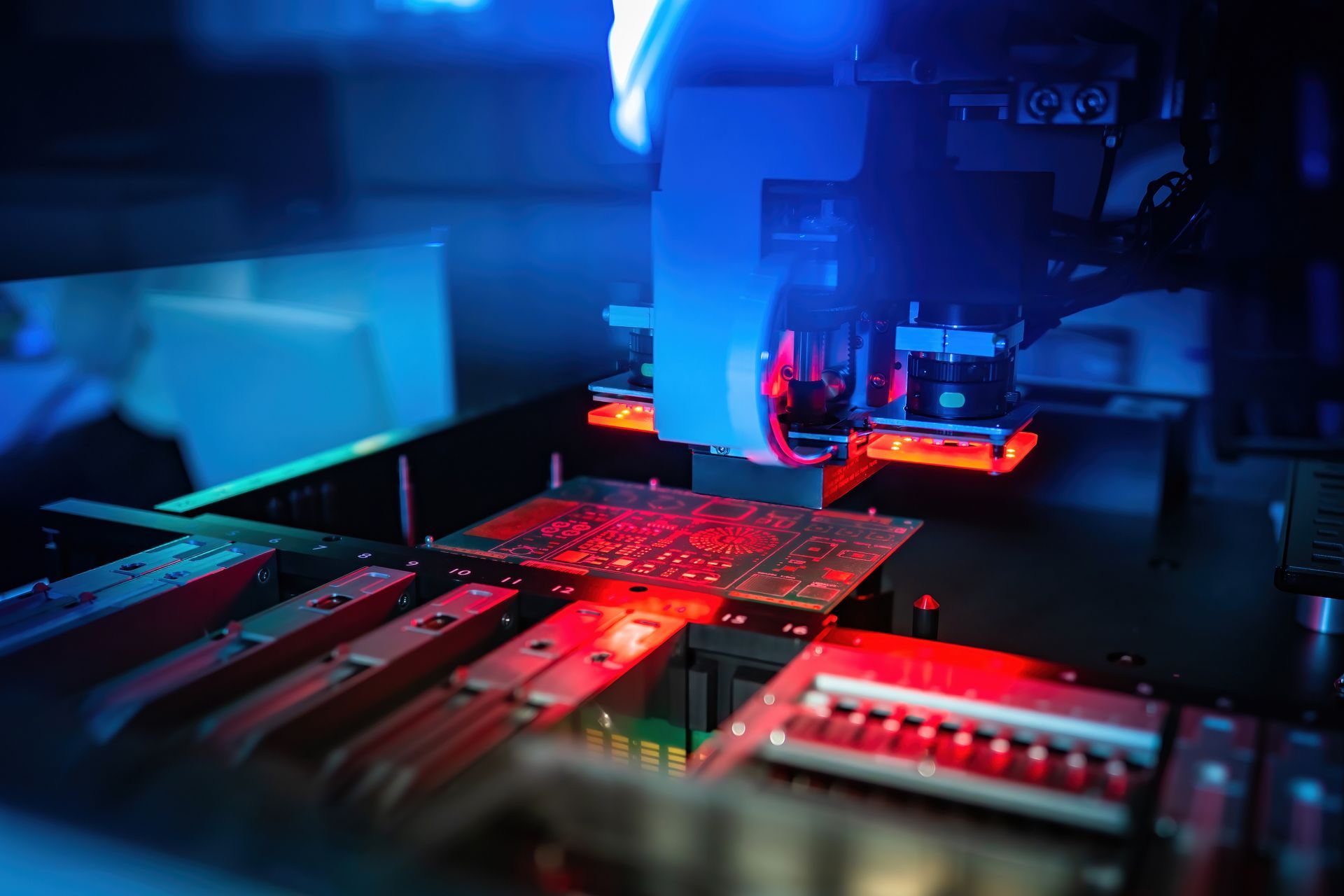

The quality of a business’s products is of the utmost importance. With the advancement of technology, businesses have access to a range of automated optical inspection (AOI) and measurement systems, including those with laser coplanarity capability. The use of this technology can improve the speed and accuracy of inspecting QFNs, LGAs, BGAs and ICs. In this article, we’ll discuss the benefits of AOI with laser coplanarity capability for these components.

Benefits of AOI with Laser Coplanarity Capability for QFNs

QFNs, or quad flat no-leads, are extremely reliable and are utilised in a wide range of applications. These components can be inspected rapidly and correctly using AOI with laser coplanarity capability. This method can detect the coplanarity of the leads of QFNs, which is critical for maintaining product quality. Furthermore, this system can detect any missing leads or misaligned components, reducing the danger of damaged products.

Since it is more accurate than traditional inspection methods, using this technology can also assist to reduce the possibility of false positives. The powerful algorithms utilised in this technology can also discover more subtle flaws that would otherwise go undetected.

Advantages of AOI with Laser Coplanarity for LGAs

LGAs, or leaded grid array packages, are gaining popularity because they enable a stable connection between the board and the component. LGAs may be quickly and accurately evaluated for coplanarity using an AOI with laser coplanarity capability, which is critical for product quality. This system can also detect any missing or misaligned components, lowering the likelihood of a faulty product.

Since it is more accurate than traditional inspection methods, using this technology can also assist to reduce the possibility of false positives. The powerful algorithms utilised in this technology can also discover more subtle flaws that would otherwise go undetected.

Benefits of AOI for BGAs

BGAs, or ball grid array packages, are gaining popularity because of their consistent connection between the board and the component. BGAs may be swiftly and accurately evaluated for coplanarity using an AOI with laser coplanarity capability, which is critical for product quality. This system can also detect any missing or misaligned components, lowering the likelihood of a faulty product.

Using this technology can also help to reduce the risk of false positives, as it is more accurate than traditional methods of inspection. The advanced algorithms used in this technology can also detect more subtle defects that might have otherwise been missed.

The Advantages of AOI with Laser Coplanarity for ICs

ICs, or integrated circuits, are used in a wide range of applications and are essential for the reliable operation of a product. With the use of AOI with laser coplanarity capability, these components can be quickly and accurately inspected for coplanarity, which is essential for the quality of the product. This technology can also detect any missing or misaligned components, which can help to reduce the risk of a defective product.

Although this technology is more accurate than conventional techniques of inspection, using it can also assist to lower the danger of false positives. This technology's sophisticated algorithms can also find more subtle flaws that could otherwise go undetected.

Conclusion

Businesses can benefit greatly from AOI with laser coplanarity capability since it can increase the efficiency and precision of inspecting QFNs, LGAs, BGAs, and ICs. This technique can determine whether the component leads are coplanar, which is crucial for maintaining the product's quality. Also, this system may find any misaligned or missing components, lowering the possibility of damaged goods. Businesses can utilise this technology to lower the danger of false positives and more efficiently find any small flaws that might otherwise go undetected.

For businesses looking to improve the speed and accuracy of their inspections, AOI with laser coplanarity capability is a must-have.

At M-Tek Assembly, we can offer a variety of services, including engineering support, testing setups and equipment, prototyping, software development, programming, and product support. Our AOI with Laser Coplanarity Capability service will help you stay competitive in your industry and boost your overall efficiency with high-quality products at an affordable price. To begin your project,

get in touch with us!