Are you looking to reduce costs and save time in the production of your electronic products? Double-sided printed circuit board (PCB) assemblies offer a great way to achieve these goals. In this article, we'll discuss the benefits of double-sided PCB assemblies and why they should be considered for your next project.

What are Double-Sided PCB Assemblies?

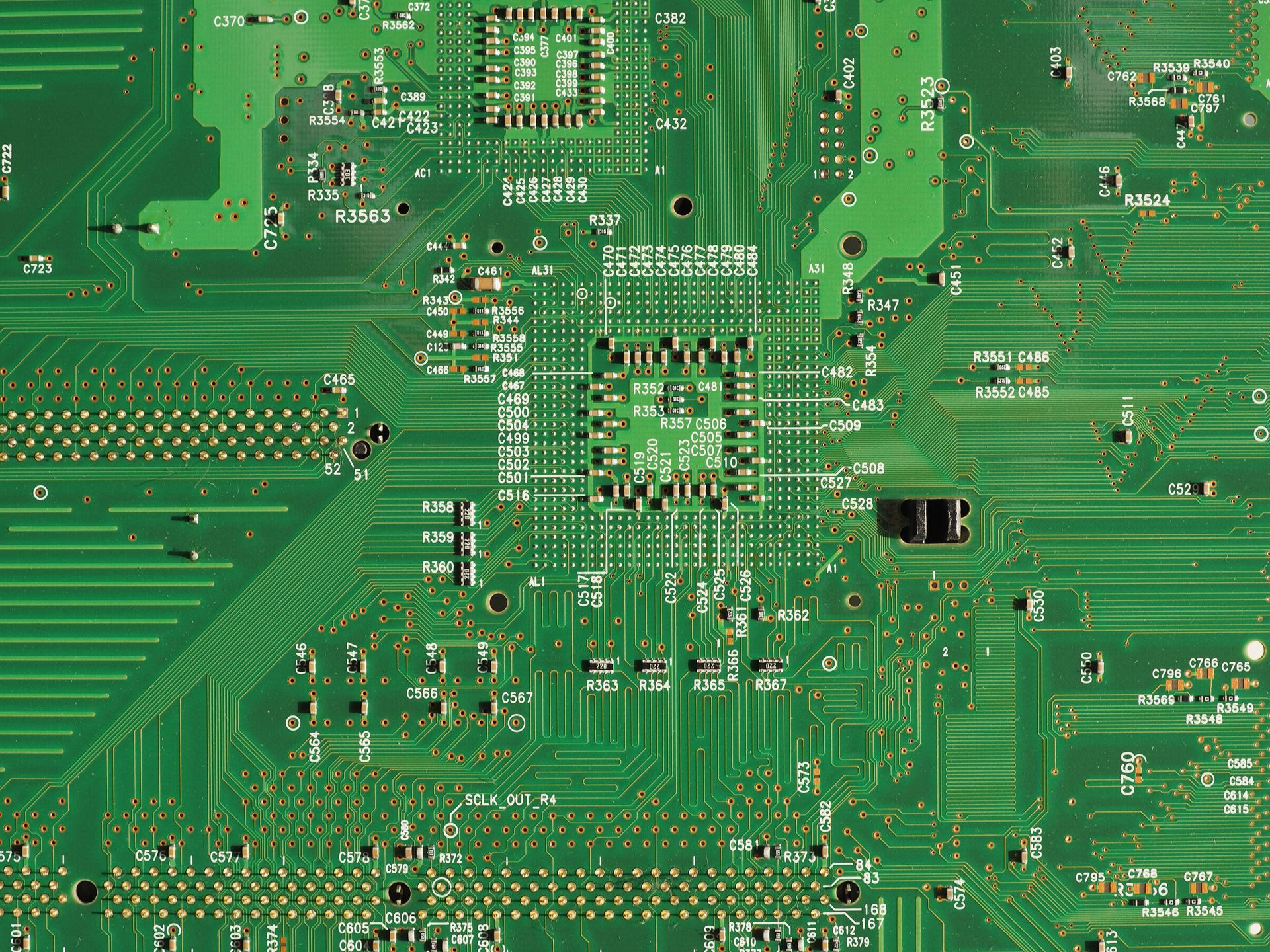

Double-sided PCB assemblies are two-layered circuit boards that feature components on both sides. This type of assembly is well-suited for medium-sized production runs, as it offers a cost-effective alternative to two-sided PCBs. As a result, double-sided PCBs are often used in industries such as aerospace, telecommunications, and consumer electronics.

Cost Savings

Double-sided PCB assemblies provide significant cost savings compared to single-sided boards. This is because components can be placed on both sides of the board, reducing the amount of material needed to complete the assembly. In addition, the cost of soldering components onto both sides of the board is significantly less than that of soldering components onto a single-sided board.

The cost savings associated with double-sided PCBs can be significant, particularly when producing large-scale projects. By utilising double-sided PCBs, businesses can reduce their production costs and maximise their profits.

Faster Production Times

Double-sided PCB assemblies also offer the benefit of faster production times. This is because components can be placed on both sides of the board, allowing for two-sided soldering operations to be completed simultaneously. This reduces the amount of time needed to complete the assembly and allows for faster turnaround times.

The faster production times associated with double-sided PCBs can be particularly beneficial for businesses with tight deadlines. By utilising double-sided PCBs, businesses can ensure that their projects are completed on time and within budget.

Increased Reliability

Double-sided PCBs are also more reliable than single-sided boards. This is because components can be placed on both sides of the board, allowing for better heat dissipation and improved signal integrity. This increases the reliability of the assembly, ensuring that it will perform as expected in the most demanding of environments.

The increased reliability of double-sided PCBs can be critical for businesses that need to produce highly reliable products. By utilising double-sided PCBs, businesses can ensure that their products will perform as expected and provide the highest level of performance.

Conclusion

Double-sided PCB assemblies offer a great way to reduce costs and increase production speeds. By using double-sided PCBs, businesses can save money on production costs and ensure that their projects are completed on time. Additionally, double-sided PCBs are more reliable than single-sided boards, providing businesses with the assurance that their products will perform as expected. For businesses looking to reduce costs and increase reliability, double-sided PCBs are an excellent option.

Here at M-Tek Assembly, we have years of industry experience, and our team of skilled engineers will guide you through the entire process. You will also be helping to save the environment by using M-Tek for double-sided printed circuit board manufacturing and repairs. We have achieved a

net-zero carbon footprint by using electric vehicles, and for every circuit board we build, we plant a tree! Contact one of our SMT and PCB assembly experts today for assistance. Call

01189 455377 or follow us on

Twitter to learn more about our services.