Efficiency plays a crucial role in the production of printed circuit boards (PCBs) for ensuring that clients receive their orders within the expected time frames.

Timely deliveries are essential to client satisfaction and maintaining a competitive edge in the market.

However, efficiency is not only important for meeting deadlines but also for promoting environmental sustainability in the electronics manufacturing industry.

Efficiency and Timely Deliveries in PCB Manufacturing

Efficiency in

PCB manufacturing directly impacts the ability of a PCB manufacturer to meet delivery time frames.

Optimised processes, streamlined workflows, and effective project management contribute to shorter production cycles, allowing for quicker turnarounds.

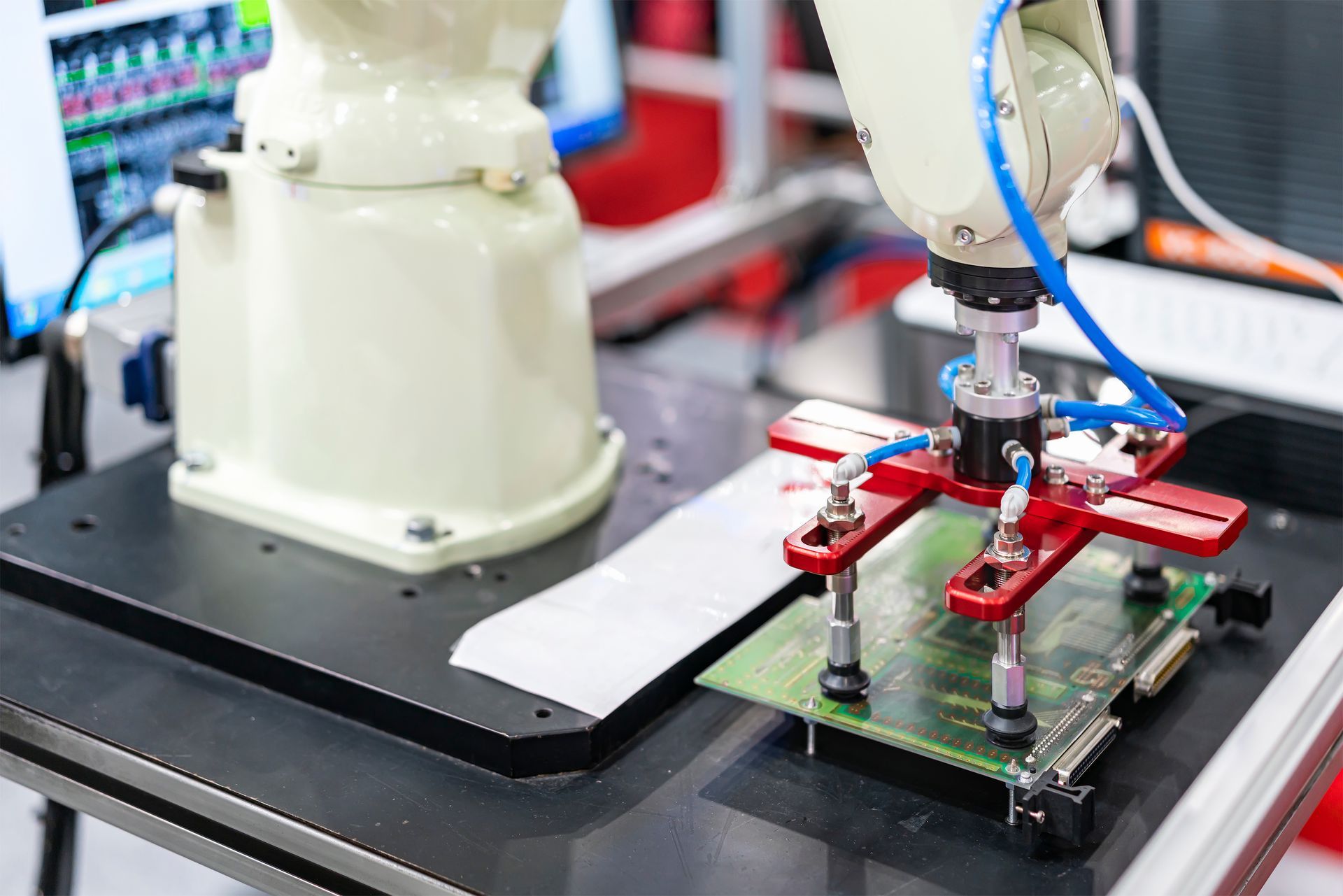

By implementing lean manufacturing principles and utilising advanced technologies, PCB manufacturers can minimise production bottlenecks, optimise resource allocation, and improve overall operational efficiency.

Efficient production planning and scheduling are essential aspects of meeting delivery time frames.

By accurately estimating the time required for each manufacturing stage, manufacturers can create realistic production schedules and ensure timely completion.

Moreover, efficient supply chain management, including well-coordinated procurement and inventory control, can prevent delays caused by material shortages or delivery issues.

Environmental Sustainability in PCB Manufacturing

Efficiency in PCB manufacturing goes hand in hand with reducing the industry's carbon footprint and promoting environmental sustainability. By optimising processes and reducing waste generation, manufacturers can significantly minimise their environmental impact.

Efficient utilisation of materials is a key aspect of sustainability. Through smart inventory management and accurate forecasting, manufacturers can minimise excess stock, reduce material waste, and lower the consumption of valuable resources. Additionally, recycling and reusing materials whenever possible contribute to a circular economy approach, further reducing the ecological footprint of PCB manufacturing.

Efficiency also extends to

transportation and logistics. By optimising routes, consolidating shipments, and implementing sustainable packaging practices, manufacturers can reduce emissions associated with transportation, minimising their carbon footprint in the supply chain. Furthermore, by employing measures such as an EV fleet, just like we do here at M-TEK, we can all come together to reduce our carbon footprint to a net zero.

Ultimately, efficiency is a crucial factor for PCB manufacturers in meeting client delivery time frames while simultaneously promoting environmental sustainability. Streamlining processes, optimising workflows, and effective project management enable manufacturers to deliver PCBs within expected timelines, ensuring client satisfaction and maintaining a competitive advantage.

Final Thoughts

In conclusion, for PCB manufacturers in the UK, prioritising efficiency is not only vital for meeting client expectations but also for building a sustainable future. By striving for efficiency in all aspects of production, PCB manufacturers can enhance their competitiveness, reduce delivery times, and make a positive environmental impact.

M-Tek Assembly

At M-Tek Assembly we have decades of experience in the field.

We have achieved a net-zero carbon footprint by using EVs, and for every PCB we build, we plant a tree!

Contact one of our SMT and PCB assembly experts today for assistance. Call

01189 455377 or follow us on

Twitter to learn more about our services, including vacuum casting.