In today's fast-paced world, where technology is advancing at an unprecedented rate, the importance of rapid prototyping in hardware development cannot be overstated.

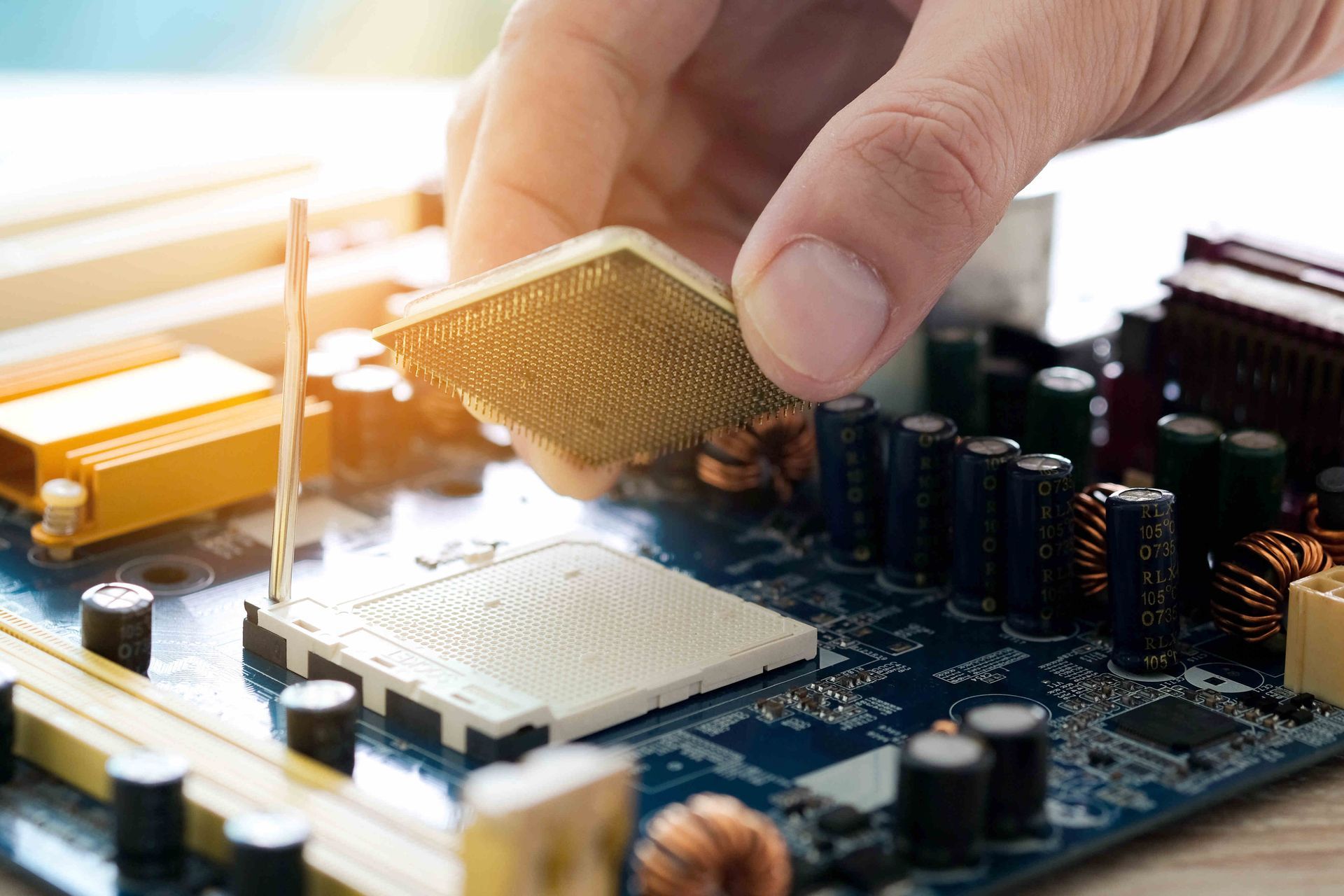

Rapid prototyping refers to the process of quickly creating physical models or prototypes of a product to validate and iterate design concepts before mass production.

This article explores the significant role that rapid prototyping plays in hardware development, its benefits, and how it accelerates innovation and efficiency in the industry.

What is Rapid Prototyping?

Rapid prototyping refers to the process of quickly creating physical models or prototypes of a product or part using computer-aided design (CAD) data. It is a technology-driven approach that enables designers and engineers to turn their concepts into tangible objects in a relatively short period

Iterative Design and Validation

One of the primary advantages of rapid prototyping in hardware development is its ability to facilitate iterative design and validation. Traditional product development cycles often involve time-consuming and costly iterations due to the lack of early feedback. However, with rapid prototyping, engineers and designers can quickly create physical prototypes and test their functionality, fit, and form.

By enabling iterative design and validation, rapid prototyping allows for faster identification and resolution of design flaws, improving the overall quality and performance of the final product. Engineers can gather user feedback, make necessary adjustments, and repeat the prototyping process, resulting in a more refined and market-ready hardware solution.

Time and Cost Savings

Time-to-market is a critical factor in the success of any hardware product. Rapid prototyping significantly reduces development time by streamlining the design and testing phases. By quickly producing prototypes, designers can verify concepts and make design improvements early in the development process, eliminating costly rework during later stages.

Moreover, rapid prototyping minimises the risk of expensive tooling and manufacturing errors. Traditional methods often require complex and expensive moulds or tools to be created before production can commence.

Enhanced Collaboration and Communication

Effective collaboration and communication are crucial for successful hardware development projects. Rapid prototyping fosters better interdisciplinary collaboration by providing tangible representations of ideas.

Prototypes also serve as powerful communication tools for showcasing product concepts to potential investors, customers, and stakeholders. They allow for early engagement and feedback, which can lead to valuable insights and necessary refinements.

Design Flexibility and Customisation

Rapid prototyping empowers hardware designers with greater design flexibility and customisation capabilities. Traditional manufacturing methods often limit design possibilities due to tooling constraints and long lead times.

In contrast, rapid prototyping techniques, such as 3D printing, enable the creation of complex geometries and intricate designs that would be otherwise challenging to achieve.

M-Tek

At M-Tek Assembly we have decades of experience within the industry. We have accomplished a

net-zero carbon footprint by using electric vehicles, and for all PCBs we build, we plant a tree. Contact one of our SMT and PCB assembly experts today for assistance on anything regarding PCBs and rapid prototyping. Call

01189 455377 or follow us on

Twitter to learn more about our products and services.