What is Surface Mount Technology?

Surface-mount technology (SMT) in electronics manufacturing simply refers to the assembly of electronic components utilising automated machines that position components on a board's surface (printed circuit board, PCB).

Surface-mount technology in electronics manufacturing simply refers to the assembly of electronic components utilising automated machines that position components on a board's surface (printed circuit board, PCB).

SMT components are mounted directly on a PCB's surface as opposed to being soldered to a wire lead, as is the case with traditional through-hole technology (THT) procedures. SMT is the method most widely employed in the industry for electronic assembly.

Along with inserting and soldering components to the PCB, the electronic assembly also includes the following production steps:

- Applying flux and tin-particle-based soldering paste to the PCB

- Attaching SMT components to the PCB's soldering paste

- Using a reflow method to solder the circuit boards.

Let’s take a closer look at the SMT assembly process!

SMT Assembly: Soldering Paste

One of the initial steps in the SMT assembly process is applying the soldering paste. The silk-screen technique is used to "print" soldering paste onto the circuit boards. Various stainless-steel stencils and product-specific pastes are employed, depending on the design of the board, to "print" the paste onto it. Soldering paste should only be applied to the regions where components will be soldered using a stainless steel stencil that has been laser-cut specifically for the project. A 2D-soldering paste inspection is carried out after the soldering paste has been applied to the boards to make sure that it has been done so accurately and uniformly. Boards are passed to the SMT assembly line, where the components will be soldered, after the accuracy of the soldering paste application has been verified.

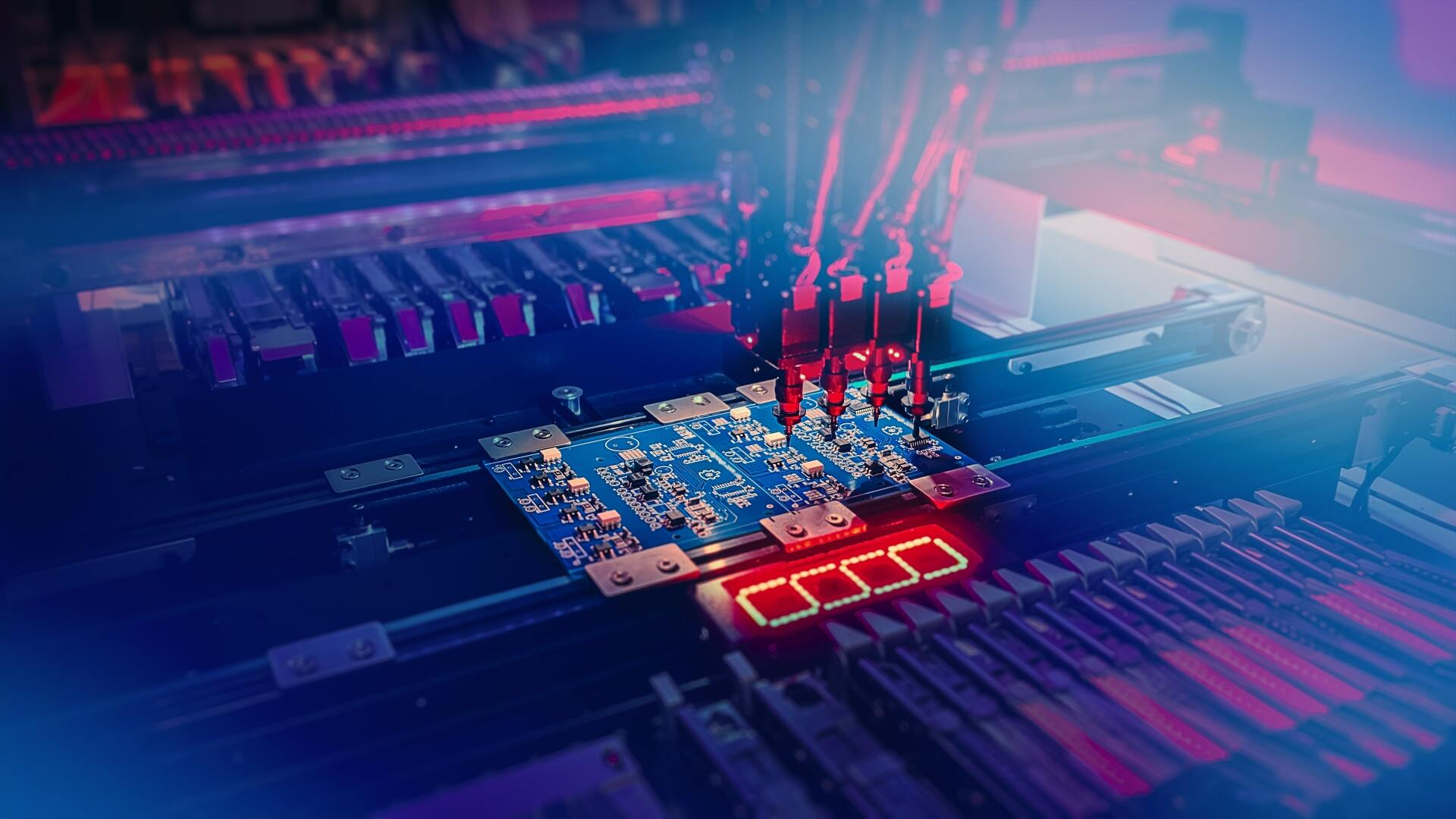

Placement and Assembly of Components

Trays or reels containing the electronic components to be assembled are fed into the SMT machine. Intelligent software systems make sure that components aren't accidentally exchanged or improperly loaded throughout the loading process. Using exact pre-programmed X-Y coordinates, the SMT assembly machine then autonomously removes each component with a vacuum pipette from its tray or reel and positions it in the proper location on the board. Up to 25,000 components can be put together by one of our machines in an hour. The boards are then sent to the reflow ovens for soldering, which attaches the components to the board, once the SMT assembly is finished.

Soldering components

Depending on the order number, we utilise one of two methods for soldering electronic components, each with specific advantages. Reflow-soldering is used for orders for serial manufacturing. Boards are placed in a nitrogen environment and gradually warmed with hot air until the soldering paste melts and the flux vaporises, fusing the components to the PCB. The boards are then cooled off after this procedure. The SMT assembly process is finished as the tin in the soldering paste dries, permanently attaching the components to the board.

We have a specific vapour-phase soldering procedure for prototypes or extremely delicate components. In this procedure, boards are heated until the soldering paste's particular melting point (Galden) is attained. Because each SMT component has a unique soldering temperature profile, this enables us to solder at lower temperatures or solder different SMT components at various temperatures.

AOI and Visual Inspection

The next-to-last phase in the SMT assembly process is soldering. AOI visual inspections are carried out for nearly all series production orders to guarantee the quality of the assembled boards or to identify and remedy a mistake. The AOI system uses many cameras to automatically inspect each board and compare its look to the appropriate, pre-defined reference image. If there are any deviations, the machine's operator is alerted to the potential issue and either fixes the error or removes the board for additional inspection. The production process for SMT assembly is consistent and accurate thanks to the AOI visual verification.

By selecting M-Tek for your SMT assembly, you will also be contributing to environmental preservation. Our usage of electric vehicles has allowed us to achieve a net-zero carbon footprint, and we also plant a tree for each circuit board we produce. To get assistance with your SMT and PCB assembly, get in contact with one of our professionals right away. Call us on 01189 455377, or follow us on

Twitter to stay up to date with our services.

Recent Posts

Call Our Team

Want to find out more about our PCB assembly services? Speak to our team to find out how we can help you.

Join the Newsletter

We will get back to you as soon as possible

Please try again later