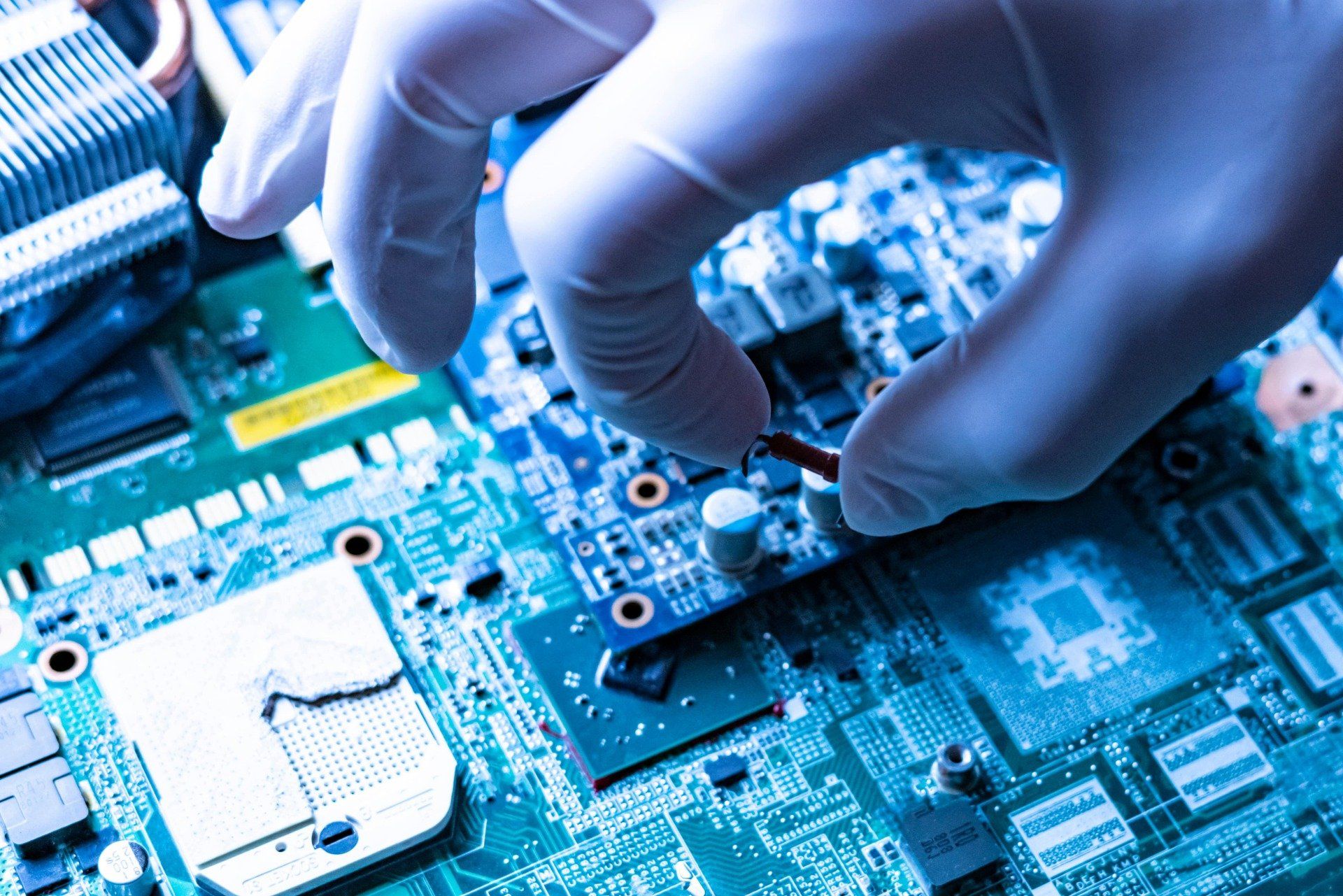

The most creative small enterprises and startups frequently discover that, when it comes to building those printed circuit boards (PCBs), they encounter some difficulties, such as the requirement to maintain a sizable inventory and have an in-house team to create it. With the shortest lead times available, turnkey PCB assembly is an electronic assembly solution that provides effective and economical ways to build and test circuit boards for new products. In this article, we'll explain what turnkey PCB assembly solutions are and what advantages they offer.

What Does Turnkey Mean in PCB Assembly?

Turnkey projects are defined as any product or service that is ready for use by the buyer. Turnkey assembly is a PCB assembly service where your supplier manages every part of the PCB project on your behalf. The supplier buys the PCB's bits and pieces and assembles them. Circuit boards are often assembled using powerful gear and cloud-based software by turnkey PCB assembly companies, who can do so more quickly and in larger quantities than small and medium businesses can.

What are the Advantages of Using Turnkey

Turnkey PCB assembly's most obvious advantage is that it spares firms from having to divert their attention from crucial activities like ongoing innovation to spend time working out the assembly details. There is no need to spend time and effort locating the greatest component prices, going through a difficult procurement process, and then needing an internal staff to expertly assemble them. The following are the main advantages of turnkey assembly:

Saves on Expenses

You save a lot of money when you use a turnkey contract because it doesn't cost extra to transfer freight to an assembly workshop. Additionally, turnkey companies enjoy favourable working relationships with component manufacturers and frequently negotiate lower part prices than small and medium-sized companies.

Identifies Issues

A significant benefit of turnkey PCB assembly is the opportunity to identify any problems before the circuit boards are incorporated into any products, which can save both time and money. You give the assembler a netlist file as part of the procedure. Before starting assembly, the assembler will make sure that the specs match the application and find any potential mistakes. You have the chance to fix the design if any mistakes are discovered, saving you from having to produce thousands of circuit boards that aren't appropriate.

Management Efficiency

Dealing with numerous vendors may be time-consuming and frustrating, especially for small organisations with scarce human resources. Because turnkey manufacturing solutions manage various channels of communication, there is a far lower possibility of a misunderstanding occurring. These potential misunderstandings could arise between you and a vendor or even between vendors, which could cause a delay in your schedule and cost you money.

Your turnkey provider will probably give you a single point of contact via which all transactions will be made, giving you peace of mind and lessening the administration strain associated with PCB assembly.

About M-Tek Assembly

Additionally, M-TEK provides comprehensive PCB services to assist you from beginning to end with everything needed for the successful execution of your PCB project. Our professional engineers will assist you at every stage of the process, and our team of PCB assembly technicians have years of industry experience.

We can offer a wide range of services, including engineering support, testing setups and equipment, prototyping, software development, programming, and product support. Our printed circuit board

turnkey assembly services will help you stay competitive in your industry and boost your overall efficiency with high-quality products at an affordable price. To begin your project,

get in touch with us!

Recent Posts

Call Our Team

Want to find out more about our PCB assembly services? Speak to our team to find out how we can help you.

Join the Newsletter

We will get back to you as soon as possible

Please try again later