What are the Benefits of 3D Prototyping for Mass Production?

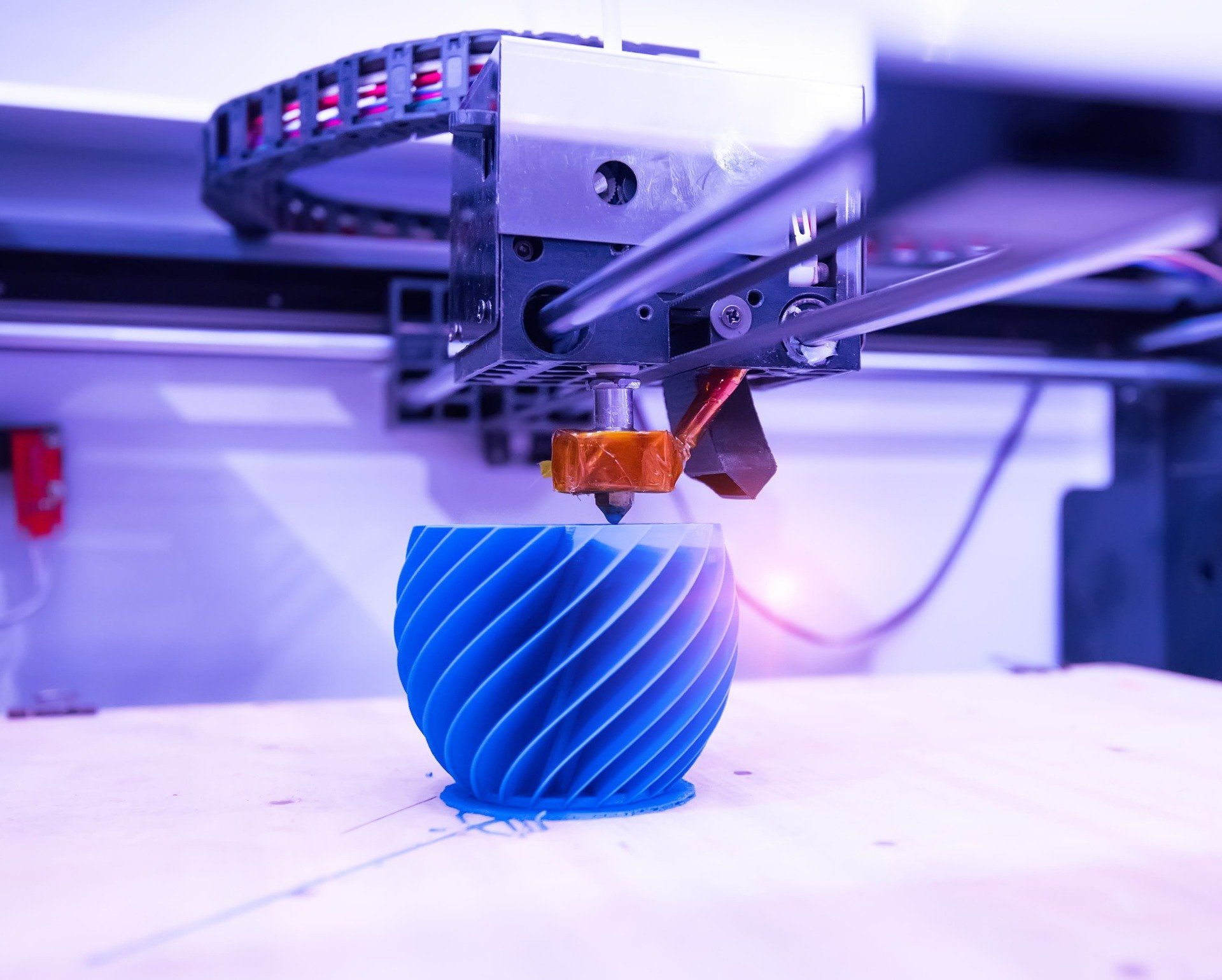

The primary call-up methods for efficiency and efficacy in production have been developed using 3D prototyping, which is a great tool for creating prototypes and real-world items. And the globe, which has tended to use rapid prototyping techniques in large manufacturing, is benefiting from 3D prototyping. Consequently, it is crucial to understand how 3D prototyping is being used in mass production, as well as its benefits and numerous applications.

3D Prototyping Allows for a Quicker Time to Market

The manufacturing industry is extremely competitive, and the amount of time it takes a product to reach the market can have a significant impact on a company's ability to succeed. This calls for the production method to be able to produce a high number of goods in a short amount of time. The business's goods will be more readily available on the market and have an advantage over rivals if manufacturing and delivery times are increased.

3D prototyping is one of the manufacturing techniques used in rapid prototyping that may create the necessary prototypes to check for problems and provide terms of the finished product. Mass production using 3D printing involves creating both finished goods and things that can aid in other manufacturing procedures. For instance, producers can utilise the method to create 3D printed injection moulds, which aids injection moulding for large production.

Versatility to Alter What You're Making Rapidly

When there is a mistake or a requirement for a change, manufacturers may quickly alter whatever they are producing with production 3D prototyping. This characteristic is crucial for 3D batch production because it enables manufacturers to create prototypes so they may inspect them for defects, evaluate how well the components work and do other tasks based on the kind of prototype they are working with. As a result, when a mistake is found, the designer may make changes quickly.

Customizability of Products

Any expanding business must meet certain basic standards for performance and appearance. Performance refers to the quality of the goods, whilst aesthetics serve to draw in clients. The ability of products to be customised affects both their performance and appearance. Production 3D prototyping is a quick prototype technique most suited to customisation among those now in use.

You can either raise or decrease output based on orders. If there is a need for a new kind of product, you may also demand a change in the design of 3D printed production parts. The variety of 3D prototyping materials also makes customisation quite simple.

About M-Tek Assembly

By using M-Tek for your rapid and 3D prototyping, you will also be helping to save the environment. We have achieved a net-zero carbon footprint through the use of electric vehicles, and we plant a tree for every circuit board we build! Contact one of our experts today for assistance with your SMT and PCB assembly. To stay up to date on our services, call us at 01189 455377 or follow us on Twitter.